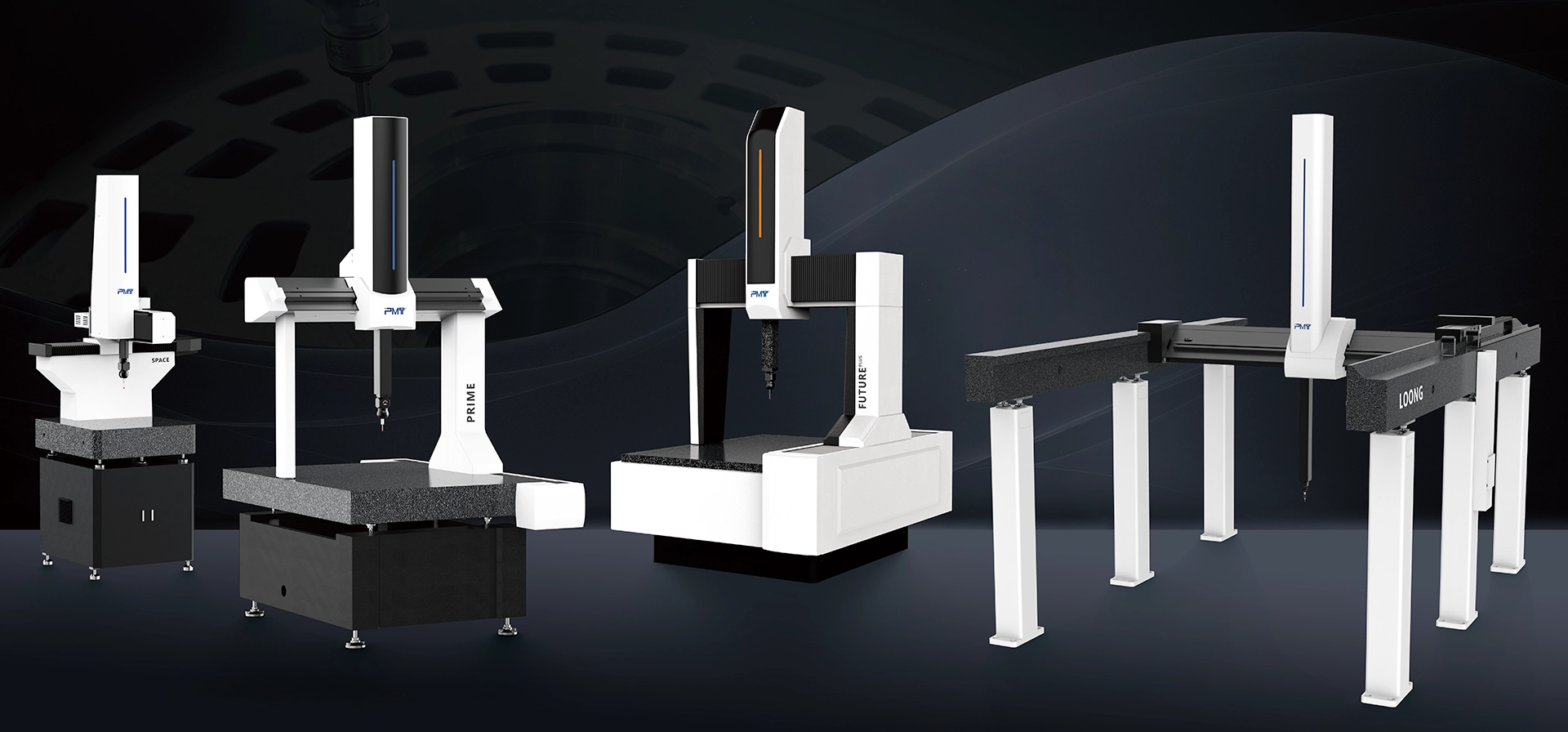

The precision and stability in tooling inspection and debugging are the key to improve the production efficiency and yield.

The primary objective of tooling testing and adjustment is to ensure the precision and stability of tooling in order to meet production requirements.

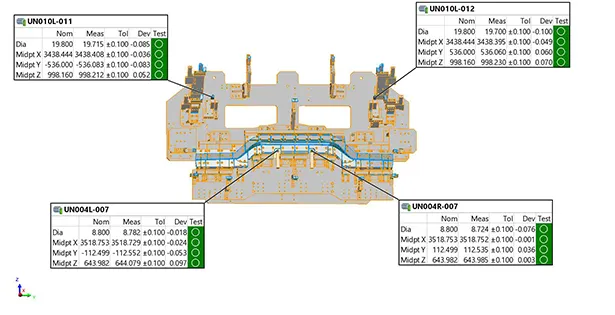

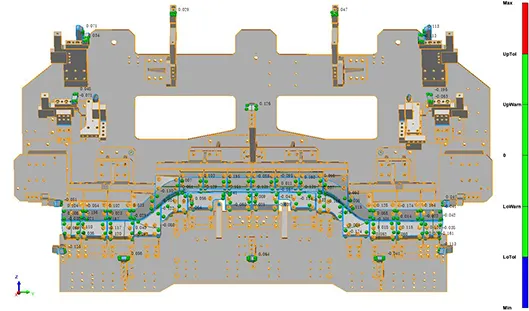

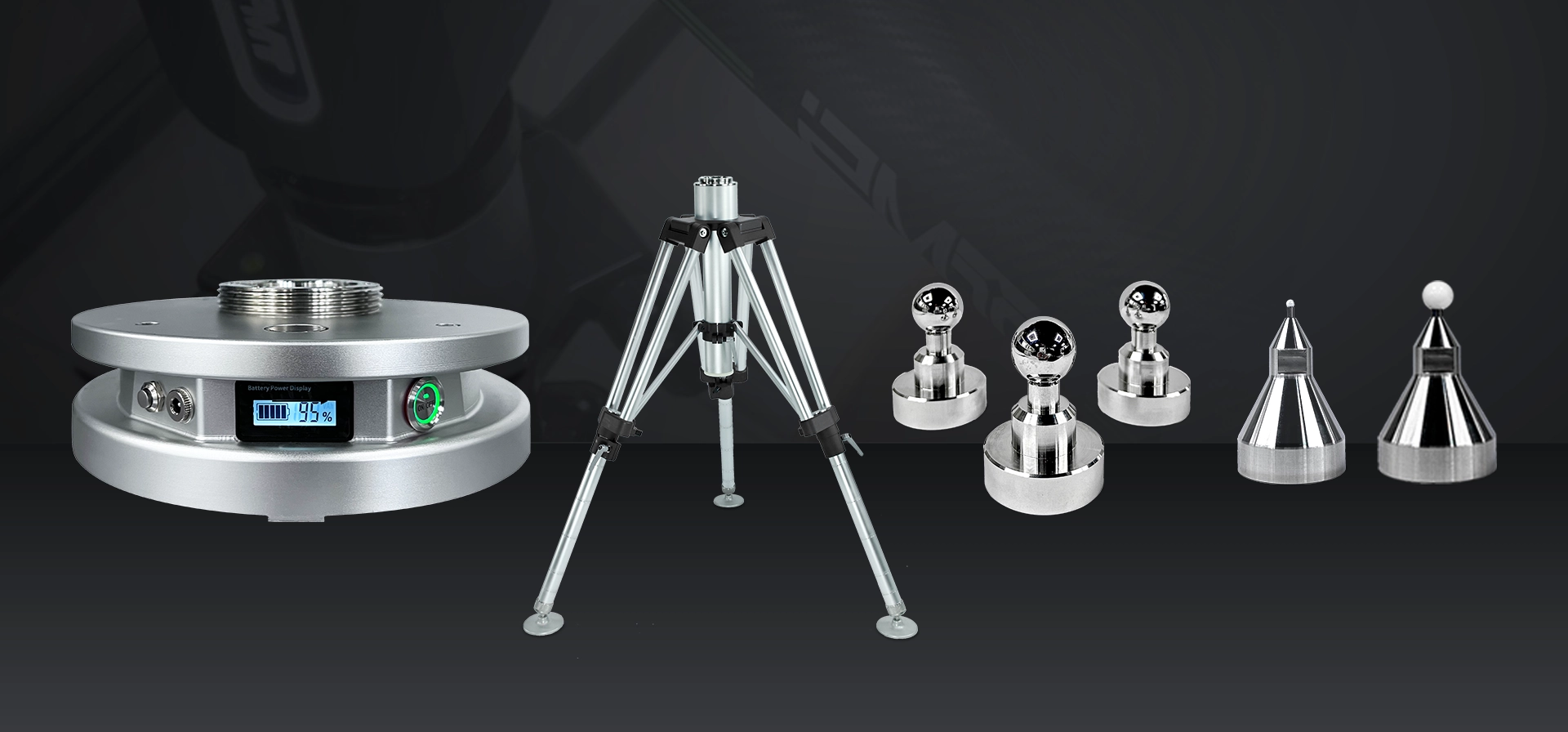

By utilizing PMT portable coordinate measurement machine, any issues with tooling, such as inadequate positioning accuracy, surface deformation or wear, can be promptly identified, leading to corresponding adjustments and optimizations. This contributes to enhancing product assembly quality and production efficiency while reducing production costs and scrap rates.