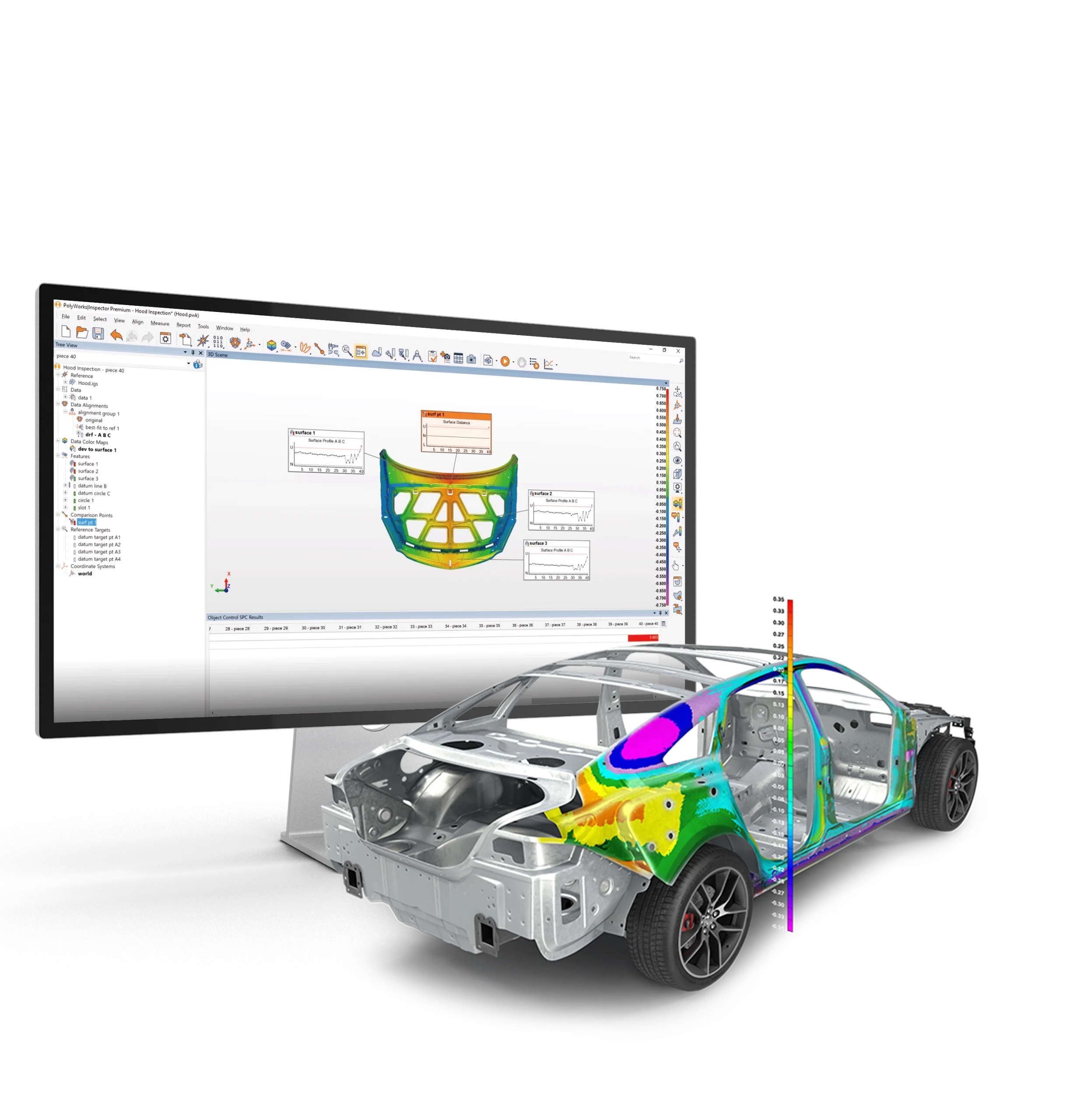

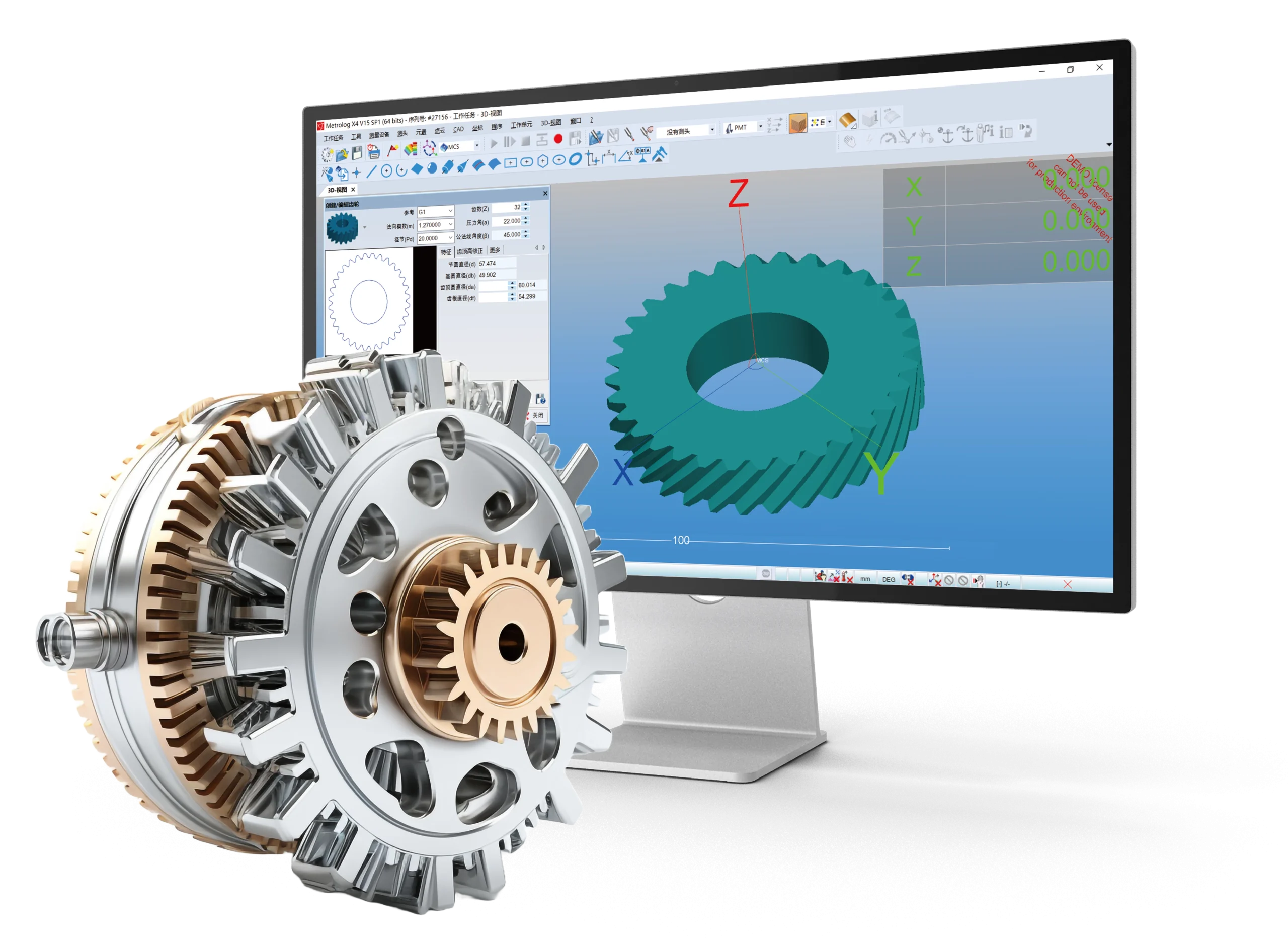

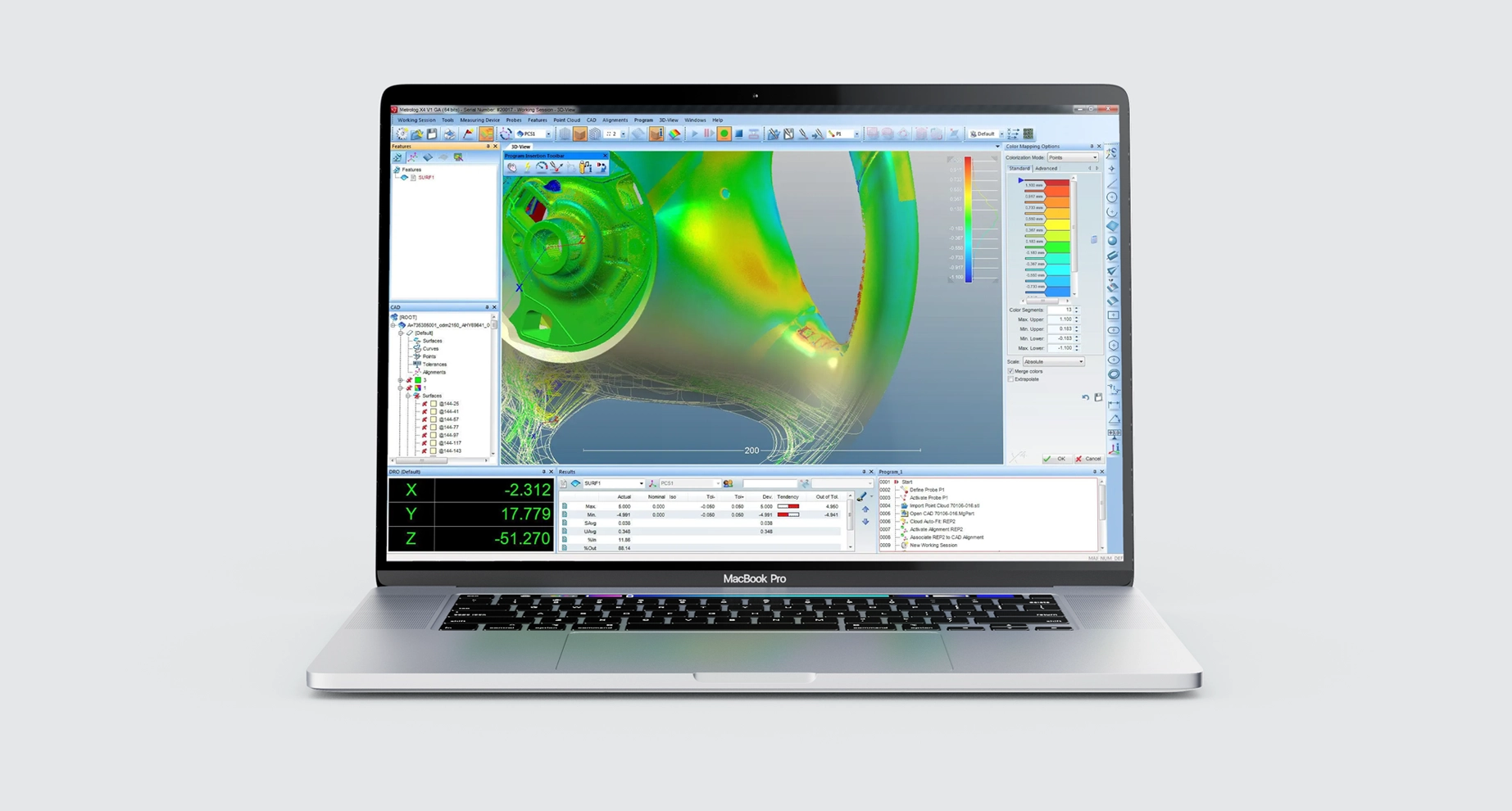

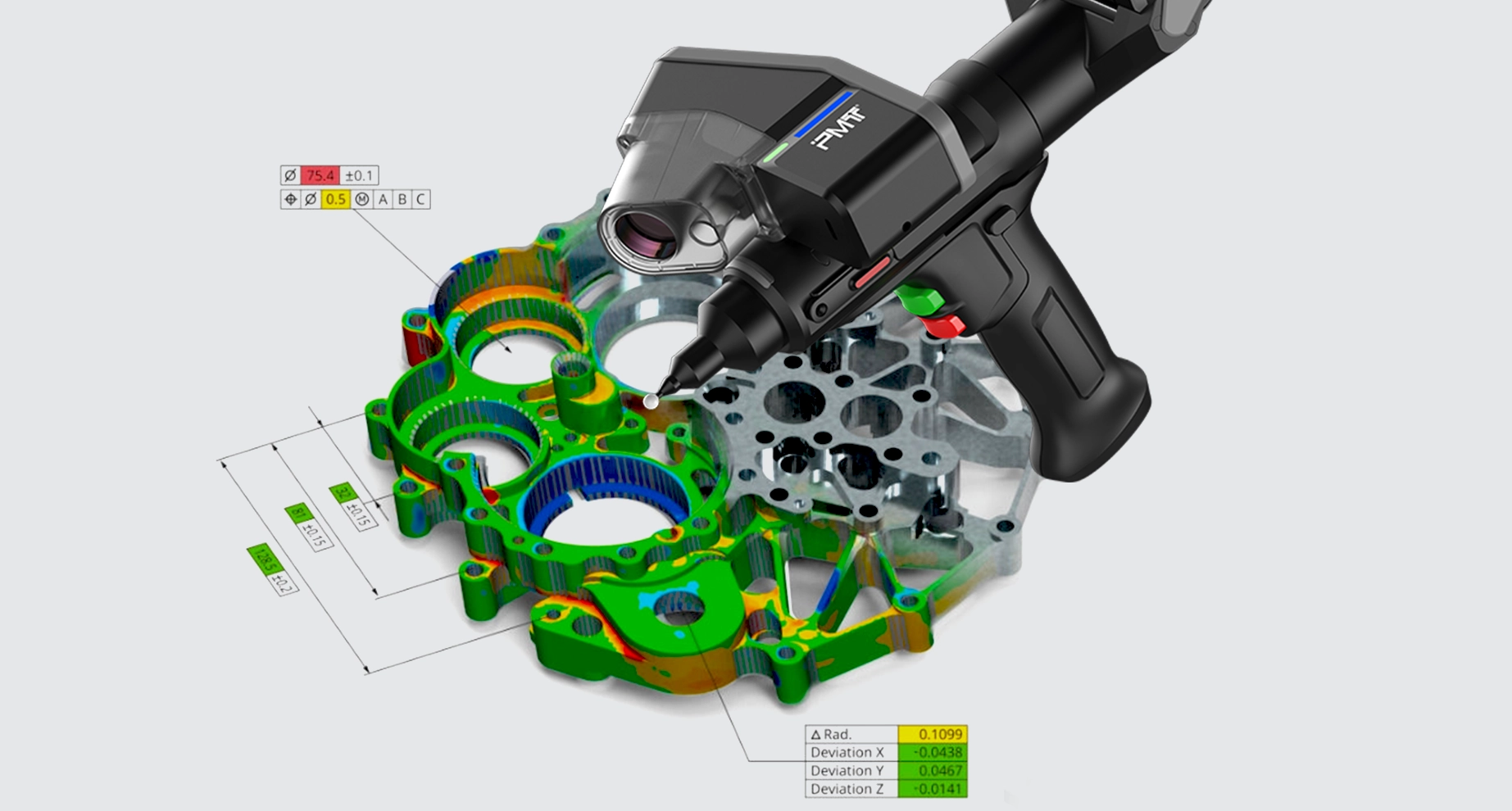

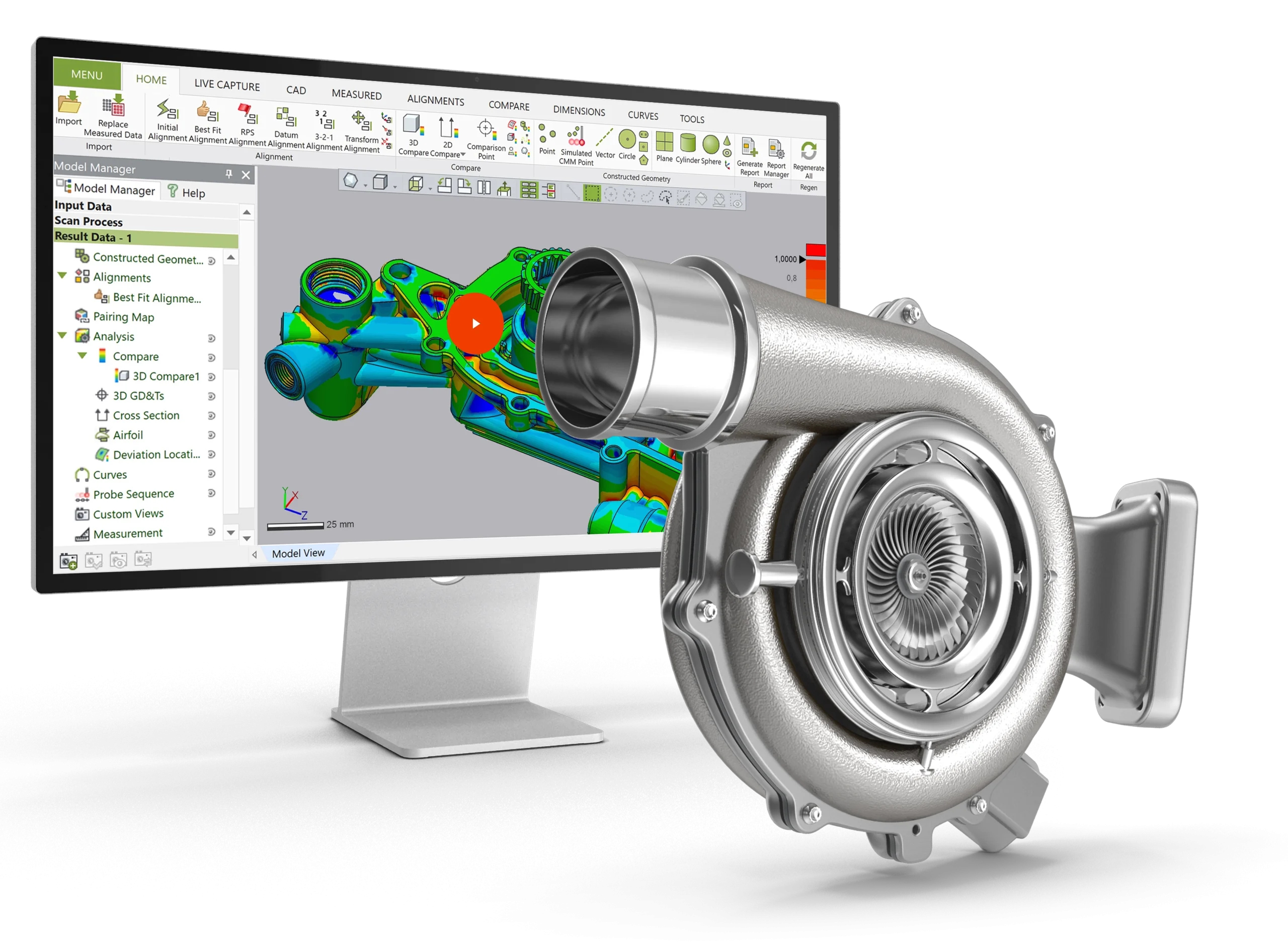

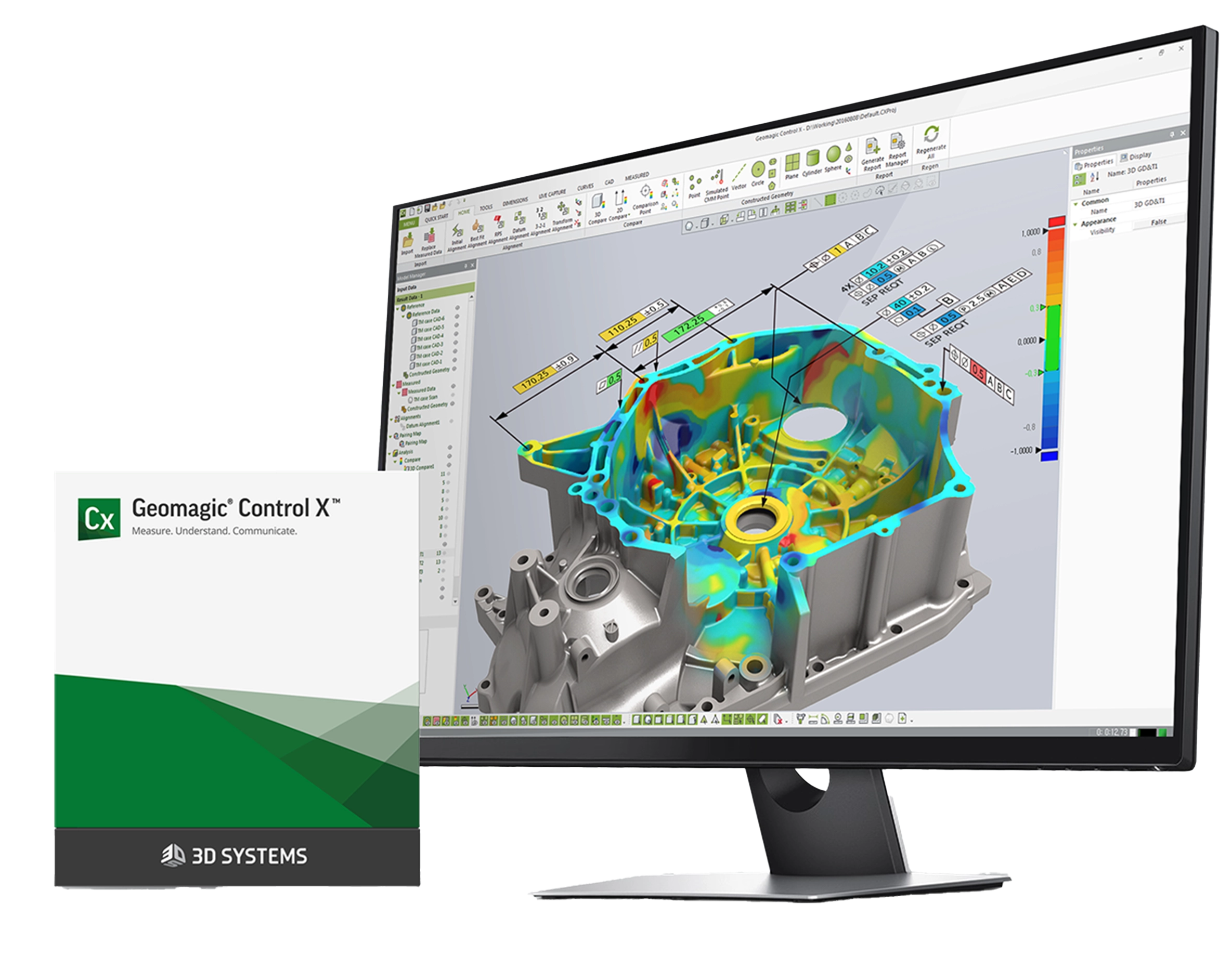

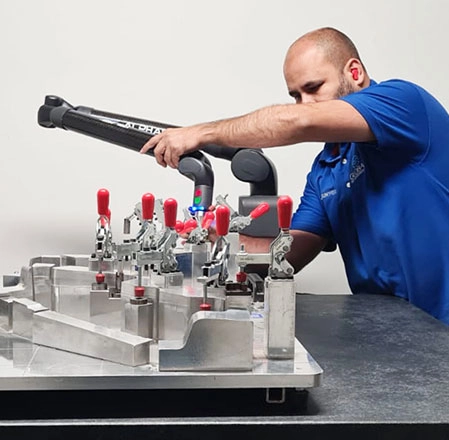

PolyWorks | InspectorTM is a universal 3D measurement software in Canada that is used for dimensional analysis and quality control. It can control the size of the measured target through real-time measurement, detect and avoid issues in production and assembly process, ensuring the quality of the assembled parts. It supports all 3D measurement workflows in industrial manufacturing and the sharing of 3D measurements among design department, production center, quality control team, and other functional departments in the organizations.