Gear is a wheel-shaped mechanical part with teeth on the rim and transmits torque by teeth engagement. It is widely used in many fields such as aerospace, automotive, shipping, wind power, construction machinery, robot, and national defense equipment. Along with the rapid progress in machinery manufacturing industry in China, it is essential to enhance the measurement competitiveness in gear manufacturing industry with high efficiency and accuracy.

Challenges

Gear is the key component of many industrial equipment. To meet high precision demand in technical parameters, size and quality, the problems in choosing suitable measurement solutions and machining methods have drawn our attention. In addition, due to the influence of geometric size and mechanical properties, the difficulties of measurement in large gears are much greater than that in small medium ones.

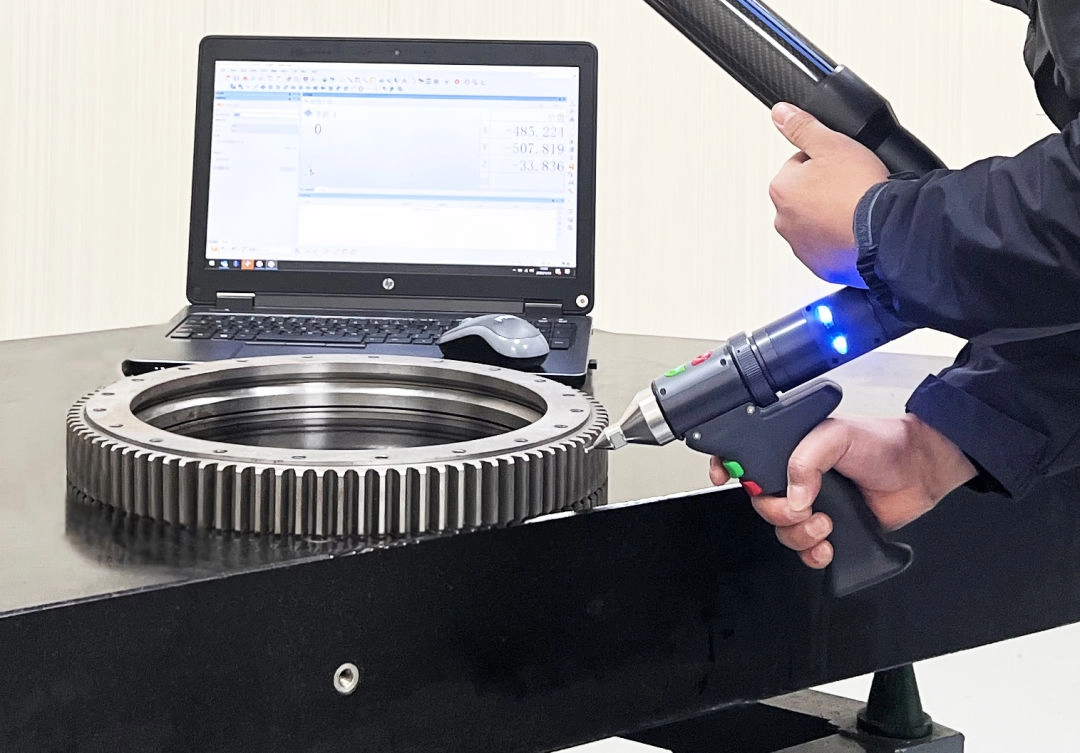

To solve the problem, PMT ALPHA ARM, by virtue of its operational ease for use and portability, can realize the high accuracy measurement of large-sized gears and gives good precision.

Gear Inspection Analysis

There are many factors that lead to bad gear accuracy, such as machining errors and tool errors. PMT ALPHA ARM supports online inspection for different gears by creating coordinate systems and generating professional reports.

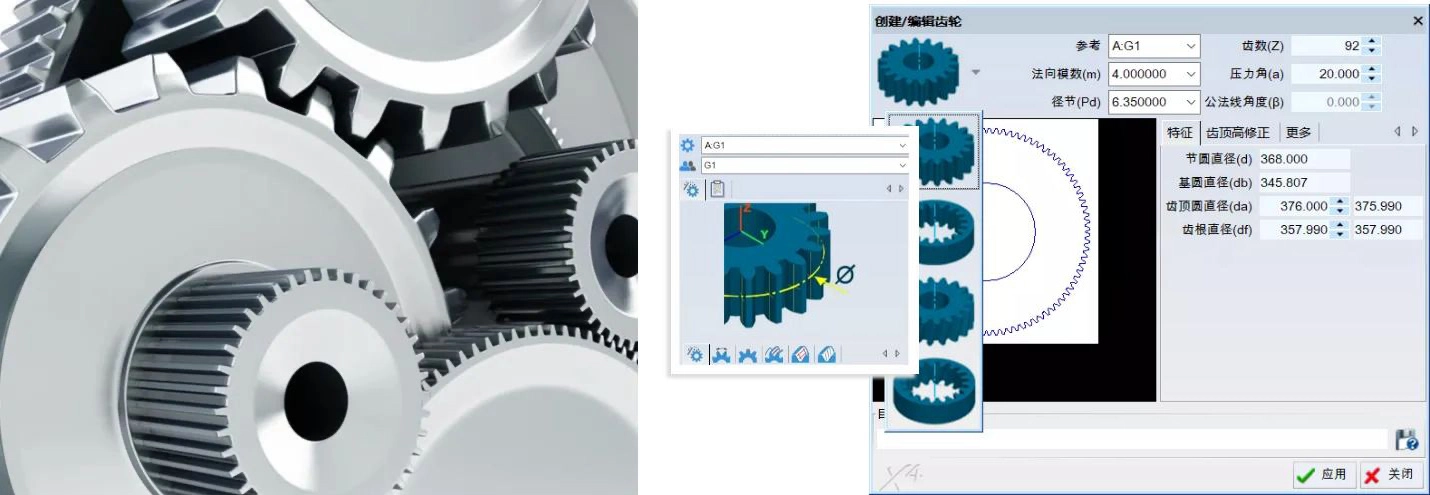

Define Gears

According to the parameters in the process drawings, choose a Gear type in the Create dialog box, setting the parameters and a CAD model is displayed in the 3D scene automatically.

Alignment

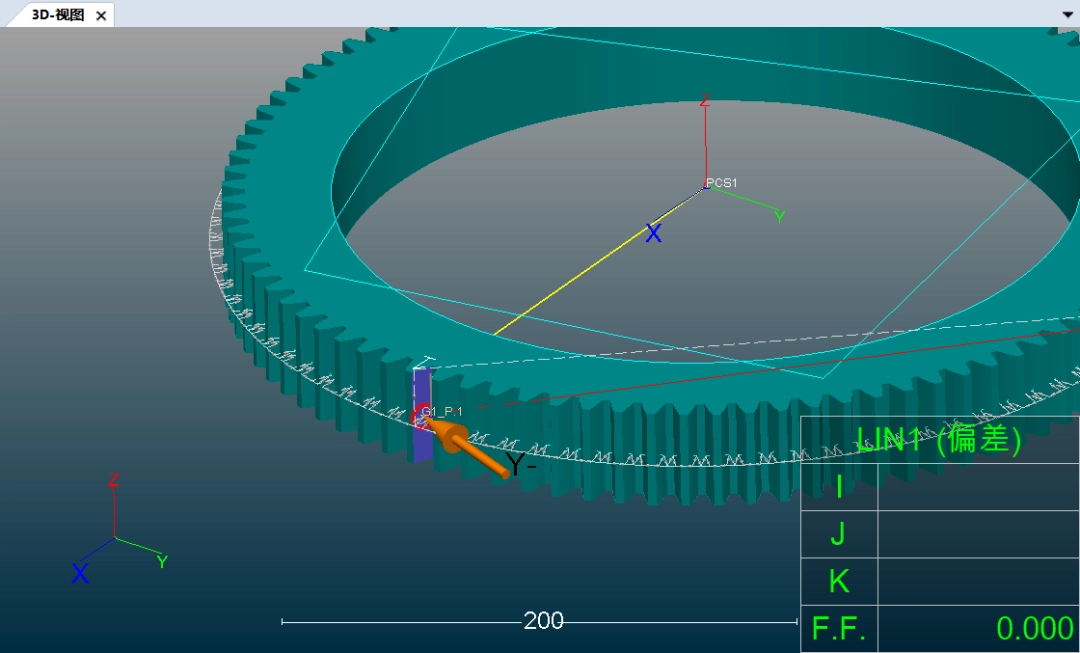

Different serial numbers are designated to each tooth of the gear through alignment in the software, in this case we use Plane-Axis-Point Alignment approach to create coordinate system. After coordinate system is established, the measuring program and path are automatically presented in the software. We can follow the arrow to finish the inspection.

Generate Report

We can generate a professional gear report when inspection is finished.

On-site Application

Gear has complex shapes. In the field measurement, it is regarded as a geometric entity to realize functions of transmission based on the whole theory error, and elementary geometrical errors can be measured through the coordinate analytical geometry method.

Multiple Installation Modes

PMT ALPHA ARM provides multiple installation modes to meet diversified demands on site, for example, circular disc integrated magnetic mount, electric vacuum clamping plate, and folding adjustable tripod. The magnetic mount features strong magnetic force and occupies less space, with which the equipment can be firmly mounted to the piece surface for easier inspection.

Fully-enclosed Structure and High-speed Wifi Performance

Thanks to its fully-enclosed structure, PMT ALPHA ARM can respond to different temperatures, humidity and multi-dust environment. The portable measuring arm can offer a smooth wireless connection and is an ideal equipment for messy and crowded workshops.

Equal-length Arm Design

The equal-length arm is designed to achieve a full-scale measurement through investing a stable equilibrium when probing positions near the base.

Intelligent Temperature Compensation System

To avoid interference from different temperatures, PMT ALPHA ARM integrates high-precision temperature sensors in each axis that can compensate errors in real time and ensure accuracy consistency in online inspection.

“The first time I used PMT portable arm to measure gears, it was very light and easier than expected. And most of our inspection work can be completed by it very quickly without finding other measuring tools everywhere. We’ve been using it for a while and felt it is much more convenient than the previous tools. We are so excited to have this portable equipment to measure our products,” said a surveyor in a gear company.

Looking back, people have been seeking for measurement solutions for gears for nearly 100 years. Looking forward, advanced measurement technology will inevitably play an important role in gear manufacturing. To this end, with a focus on the field of portable measurement, PMT will continue to refine, enrich, update and improve its technologies so that it will provide more effective technical means to enhance the core competitiveness of gear production. In this way, PMT will promote the transformation and upgrading, and deepen the development of the gear manufacturing industry.