Metal One Co., Ltd. China Factory – Hangzhou Metal One Steel Products Processing Co., Ltd. has conducted its first collaboration with PMT, using the PMT ALPHA E 3.5m to measure engineering machinery parts, greatly improving processing quality and taking its production progress to a new level.

Cooperation Background

Metal One was founded in 2003 through the merger of the steel business divisions of Mitsubishi Corporation and Nissho Iwai Corporation. For numerous years, it has remained at the leading position in the steel industry. Metal One has made investments in over 20 metal products companies in China, among which Hangzhou Metal One mainly concentrates on steel plate cutting, processing of steel plate cutting products, and processing of incoming materials. By innovating the value chain of the metal circulation industry and leveraging the experience accumulated in the Japanese steel circulation field over an extended period of time, it undertakes business development for Chinese customers.

What sets Metal One in Hangzhou apart from Metal One in other regions is that in the past, measurement work at Metal One in Hangzhou was completed using traditional two-dimensional tools (calipers, angle gauges, etc.) and the accuracy of the results was heavily dependent on the skills of the operator, and it was still unable to handle certain complex structures, which was time-consuming and labor-intensive. These factors led Metal One in Hangzhou to realize that it was urgent to find a better solution. In the end, Metal One in Hangzhou looked to its headquarters for inspiration and focused on portable three-dimensional measurement tools, purchasing a PMT-ALPHA E measurement device.

Effective Solution

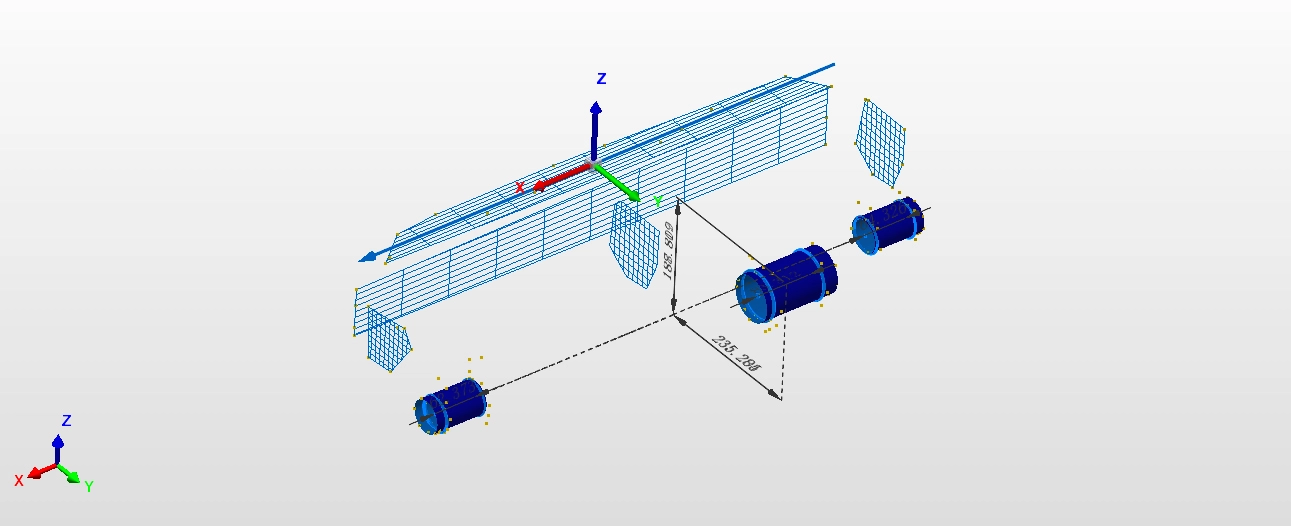

3D measurement entails the integration of computer-aided design and prototype manufacturing. PMT 3D Measure Solution is capable of measuring complex structures on parts, such as GD&T. Through merely the application software, one can promptly acquire detailed and comprehensive measurement reports in a graphic and textual format, facilitating on-site data analysis and evaluation of part quality.

With the help of 3D software, multi-part measurement commands can be used. During the process, measurement templates can be established to enable one-click report output, reducing the number of data editing steps.

This approach is capable of enhancing productivity by 50%, which was previously unimaginable in the past.

Firm Choice

As a leading enterprise in the engineering machinery industry, Metal One has multiple factors to consider when choosing measurement equipment. In principle, it should choose equipment from the same brand as its headquarters. However, after in-depth exchanges, on-site demonstrations, on-site inspections, and comprehensive comparisons with PMT, Metal One Hangzhou ultimately chose PMT firmly. In the future, we are convinced that there will be greater cooperation space between the two sides!