In modern manufacturing, Coordinate Measuring Machines (CMM) play a crucial role in ensuring high product quality. These precision tools measure the physical geometrical features of objects with unmatched accuracy. However, like any advanced technology, CMMs can encounter issues that may disrupt their performance. Understanding these problems and knowing how to troubleshoot them can save valuable time and prevent costly errors. In this article, we’ll explore the most common issues with CMMs and provide practical solutions to address them.

Common Issues with CMMs

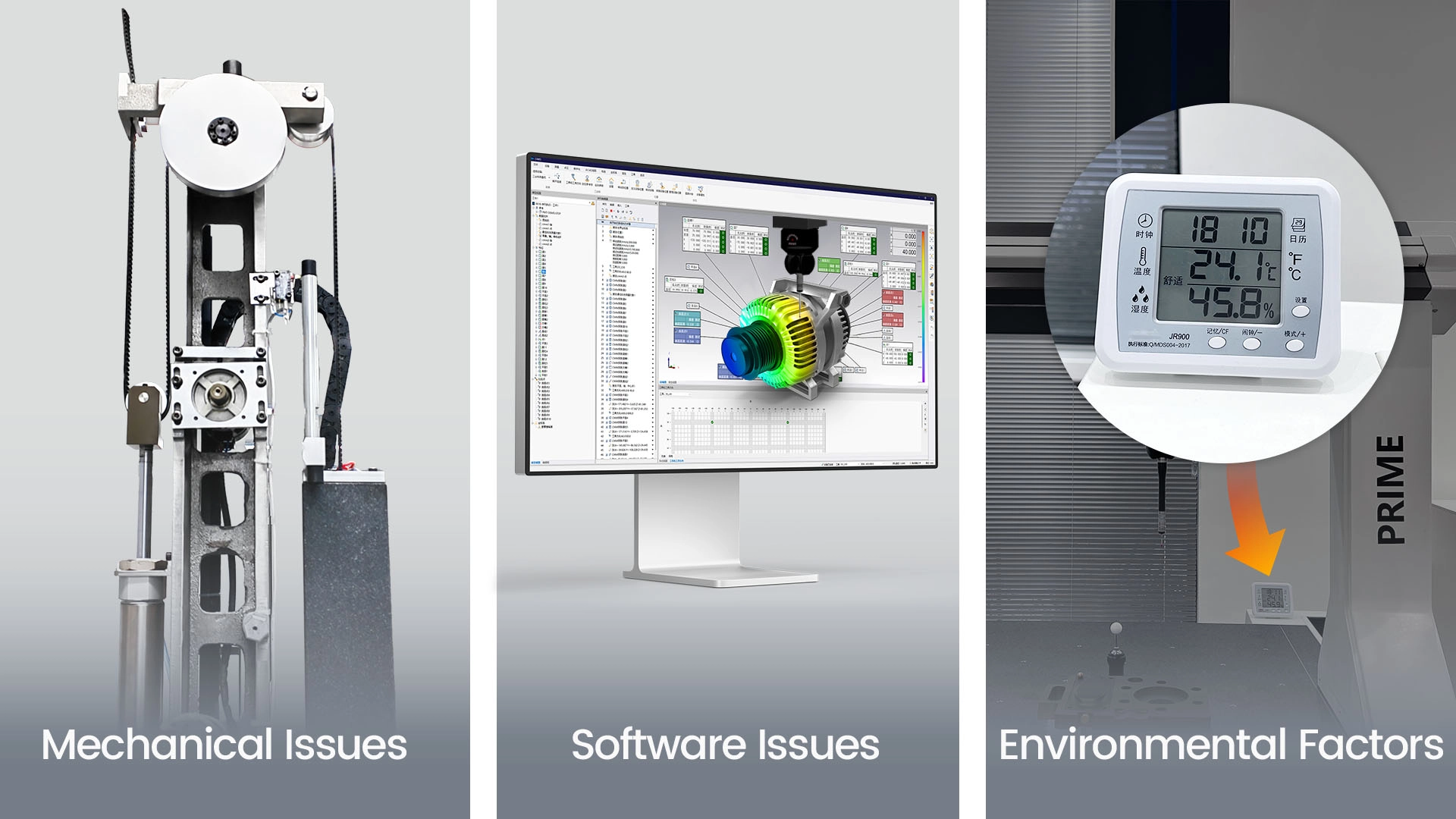

CMMs can face a variety of problems that affect their operation. These issues generally fall into three broad categories: mechanical, software, and environmental factors. Recognizing the symptoms of these problems early on is key to maintaining the accuracy and efficiency of your machine.

1. Mechanical Issues

Mechanical problems in a CMM are often caused by wear and tear on the machine’s moving parts. Over time, components such as guide rail, bearings, and probes may become damaged or misaligned, leading to inaccurate measurements.

For example, when bearings wear out, the movement of the machine can become jerky or imprecise, causing a loss of repeatability. Similarly, damaged probes may fail to make proper contact with the part, producing faulty readings.

To prevent mechanical issues, it’s essential to perform regular visual inspections and functional tests. If any components show signs of wear, they should be replaced immediately to maintain the CMM’s accuracy.

2. Software Issues

Just as mechanical problems can affect the accuracy of measurements, software issues can cause the CMM to function improperly. Problems can arise from outdated software versions, compatibility issues with other systems, or even corrupted files. These errors can lead to incorrect data processing, faulty measurements, or system crashes.

To avoid software-related issues, always ensure your CMM software version is compatible with the controller firmware. Certified metrology solution providers, such as PolyWorks and Metrologic, regularly release the latest versions that will optimize performance and resolve potential software issues as well. Additionally, operators should receive proper training to handle the software effectively, reducing the risk of errors due to user mistakes.

3. Environmental Factors

The environment in which a CMM operates is another crucial factor that can affect its performance. Temperature fluctuations, humidity, dust, and even vibrations can cause inaccuracies in measurements. For instance, temperature changes can cause the machine’s components to expand or contract, leading to errors in measurement.

To mitigate the impact of environmental factors, it’s essential to maintain a controlled environment for the CMM. This includes keeping the machine in a temperature-controlled area, controlling humidity levels, and minimizing dust or other contaminants that could interfere with the machine’s delicate components.

Troubleshooting Strategies

When a CMM encounters issues, a systematic approach to troubleshooting can help resolve the problem quickly and efficiently. Let’s walk through some of the most effective troubleshooting strategies.

1. Regular Calibration

One of the most important aspects of maintaining a CMM accuracy is calibration. Calibration is the process of comparing the measurements made by the CMM to known reference standards, and adjusting the machine as needed to ensure its accuracy.

To avoid inaccurate measurements, it’s essential to perform regular calibration checks. PMT Technologies offers tailored calibration training sessions based on the frequency of use, environmental conditions, and machine specifications. Keeping the machine calibrated will help ensure its precision over time.

2. Software Updates and Operator Training

Another key step for troubleshooting is to update the CMM software. Software updates not only fix bugs but also improve functionality, helping the machine stay compatible with the latest systems and technologies.

Additionally, operators should receive regular training to stay updated on the software’s features and to learn best practices for running the machine. Proper training helps prevent human errors that could lead to inaccurate measurements or machine malfunction.

3. Environmental Control

Controlling the environment around the CMM is crucial to its optimal performance. To prevent machine accuracy degradation caused by temperature variations, high humidity, and dust contamination, it’s important to store the CMM in a stable environment with controlled temperature and humidity levels. Additionally, minimize exposure to vibrations or any external factors that could cause the machine to deviate from its precise measurements. Using vibration isolation tables or placing the machine in cleanroom-like conditions can significantly improve measurement reliability.

Advice from PMT:

- Operating Temperature:

- SPACE Shop Floor CMM: 15-30°C

- FUTURE, PRIME, LOONG Series: 20±2°C

- Relative Humidity: 40%-70%

4. Preventive Maintenance

Preventive maintenance involves regular checks and the replacement of worn-out parts before they fail. This approach can save you from unexpected breakdowns and costly repairs in the long run. Key maintenance tasks include cleaning the machine regularly, inspecting moving parts for wear, and replacing parts such as bearings or probes when necessary.

A preventive maintenance schedule should be created based on the PMT’s guidelines, ensuring that all aspects of the CMM are routinely checked. Proactive maintenance helps extend the machine’s lifespan and keeps it operating at peak performance.

Conclusion

Troubleshooting and maintaining a CMM are essential for ensuring its continued performance and precision. By understanding the common mechanical, software, and environmental issues, and following proven troubleshooting strategies, you can minimize downtime and keep your measurements consistent. Regular calibration, preventive maintenance, and a controlled environment will go a long way in maintaining the accuracy of your CMM, ensuring it meets the high standards required in today’s manufacturing and engineering sectors.

FAQs

- How often should CMMs be calibrated?

Calibration should be performed at least once a year or as recommended by the manufacturer, depending on usage and environmental conditions. - What are the most common mechanical issues with CMMs?

Common mechanical issues include wear and tear on bearings, probes, and scales, as well as misalignment of the CMM’s components. - How does temperature affect CMM accuracy?

Temperature fluctuations can cause the machine’s components to expand or contract, which leads to errors in measurements. - Can software updates really improve CMM performance?

Yes, software updates fix bugs, enhance functionality, and add features, which can improve the overall accuracy and performance of the CMM. - What are the best practices for CMM environmental control?

Maintaining a stable temperature, controlling humidity levels, and keeping the area free from dust and vibrations are key for optimal performance.

For expert advice on CMM calibration, preventive maintenance, and troubleshooting, contact PMT today. Our comprehensive CMM solutions ensure high-quality, accurate measurements and a streamlined manufacturing process.