The post Blockbuster News|Live from PMT at CIMT – Sneak Peek at CIMT Highlights! appeared first on PMT.

]]>

Live Highlights|PMT Booth Draws Global Crowds Attention

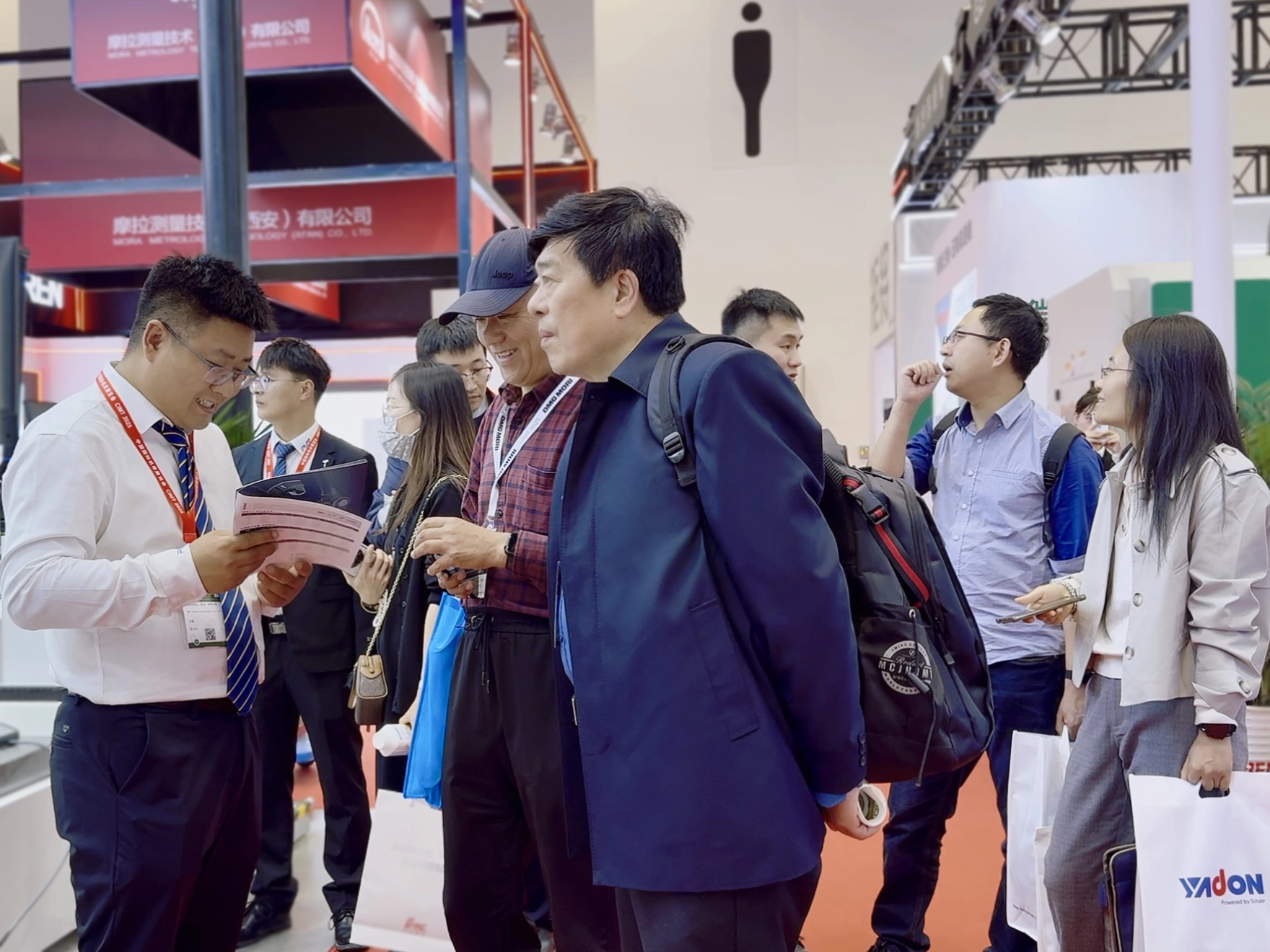

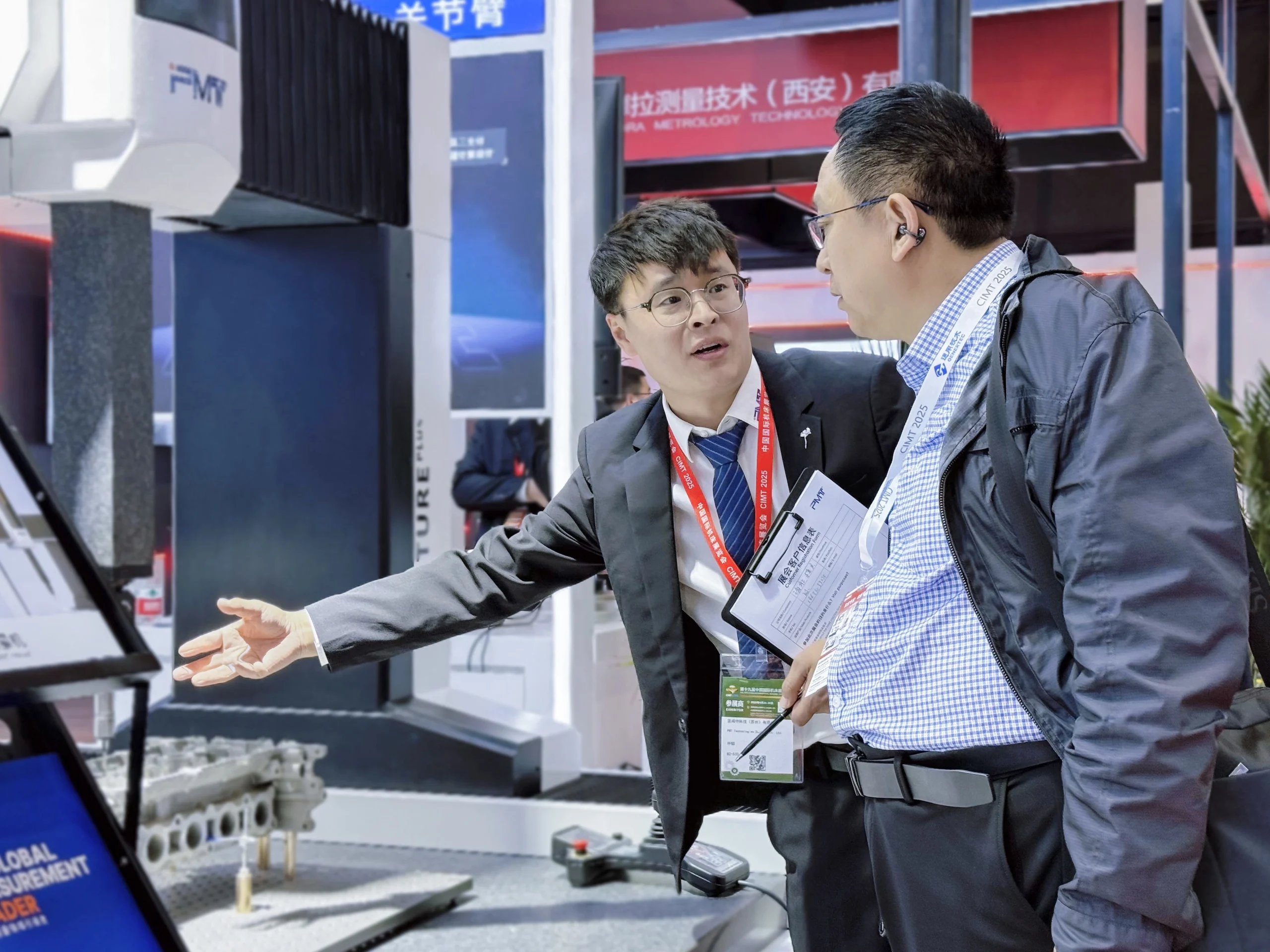

In-Depth Dialogues Driven by Intelligent Manufacturing

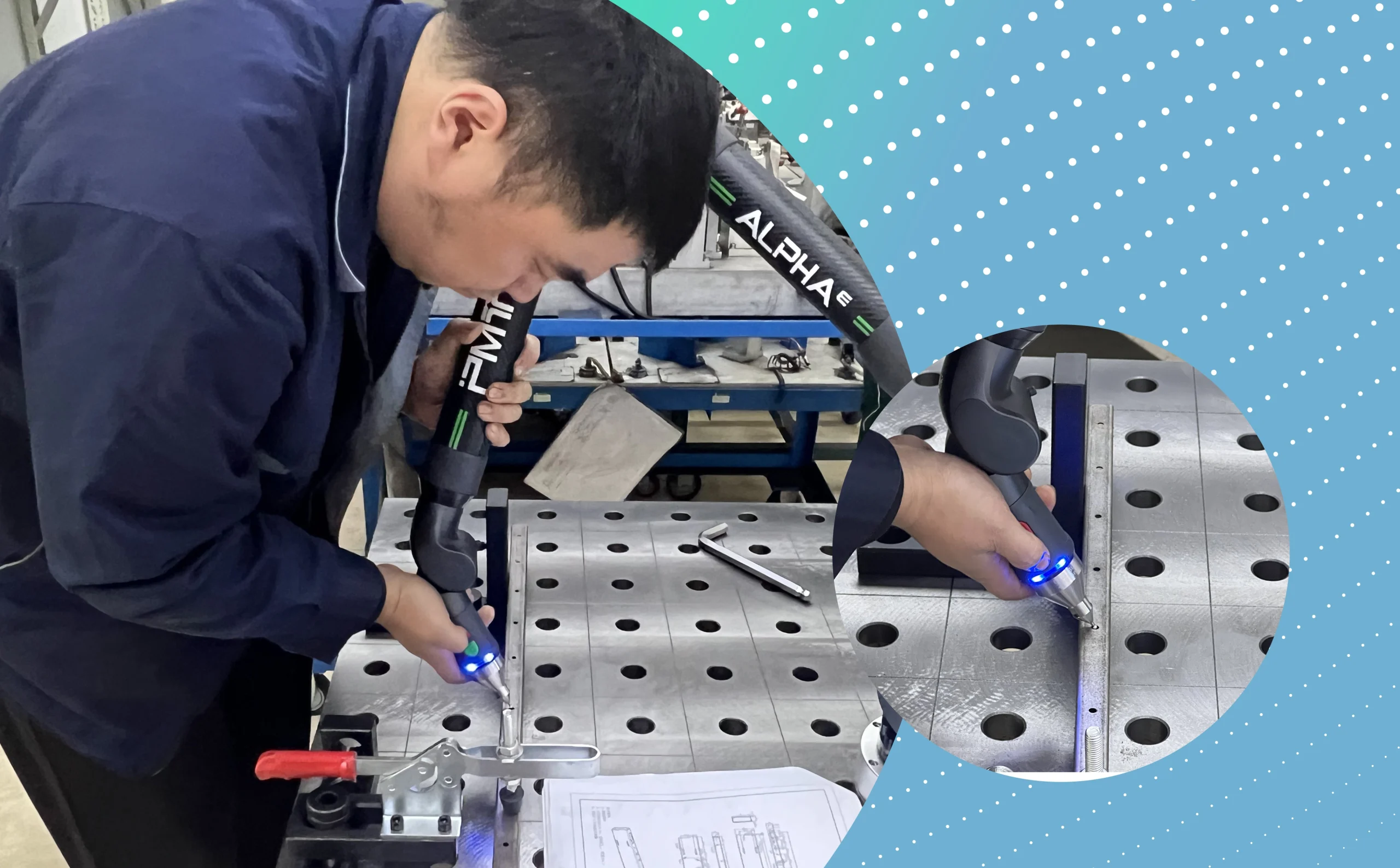

At PMT booth, professional visitors and industry decision-makers from over 20 countries, including Germany, Russia, Singapore, the Philippines, Thailand, and India, engaged in in-depth discussions with the PMT team. They experienced live demonstrations of the “New-Generation Portable Coordinate Measuring Machine” and detailed technical insights into the CMM machine, showing strong interest in establishing collaboration with PMT.

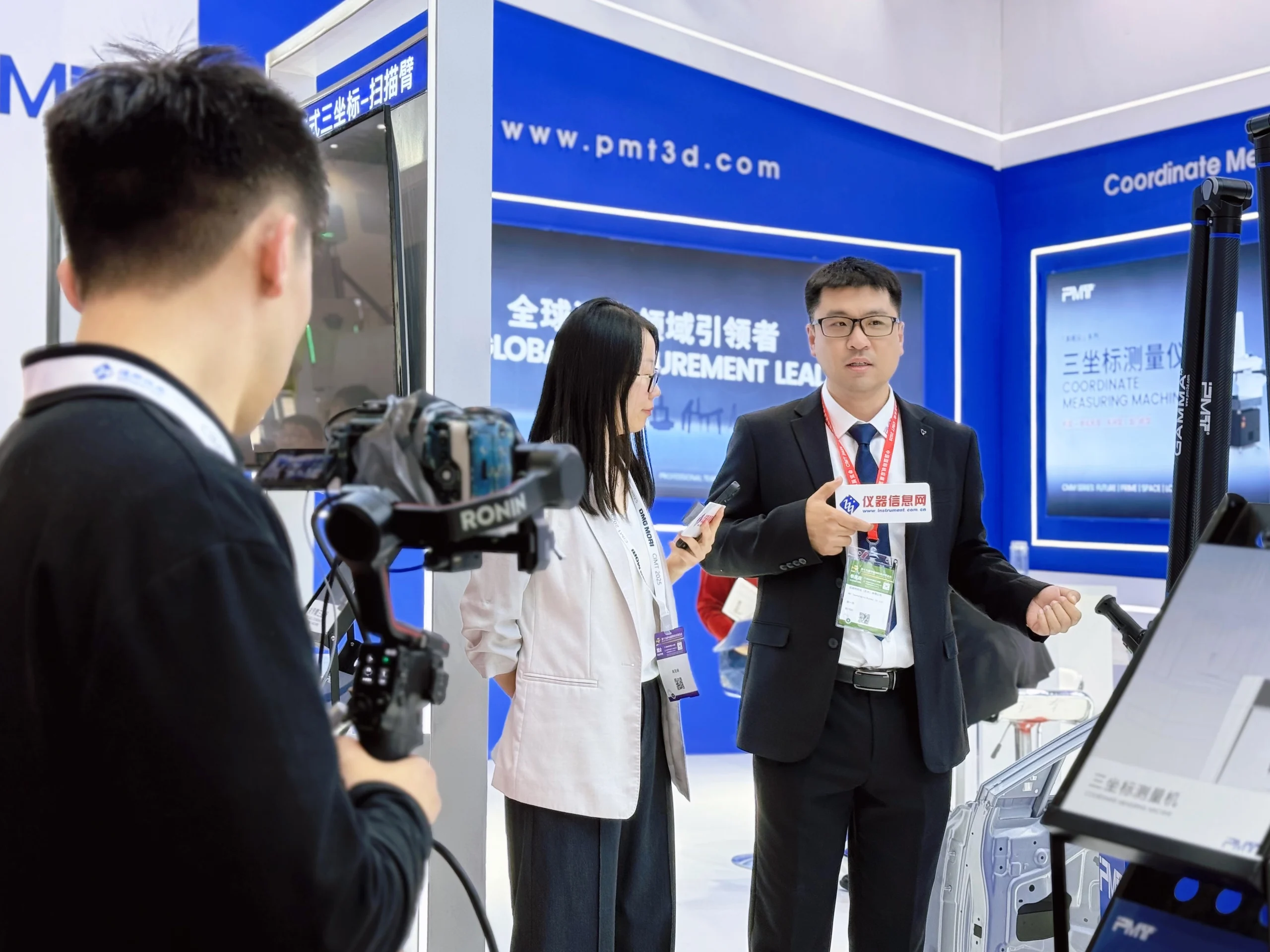

Recognized by the Media, Trusted by the Industry

PMT remains committed to providing high-precision, intelligent measurement solutions for the global industry with its star products such as articulates arm cmm, types of coordinate measuring machine. At Exhibition, PMT has also caught the attention of key media outlets. Representatives from the CIMT organizing committee and Instrument.com.cn visited the booth to get a closer look at PMT coordinate measuring arm and 3D arm scanner, and carry out exclusive interviews. Discussions focused on PMT’s role in accelerating the development of high-precision measurement in the era of Industry 4.0. PMT’s North China Regional Manager, EJ, was invited to share expert insights in terms of PMT’s 3D scanning arm and CMM machine during a live broadcast titled “Smart Metrology for the Future.”

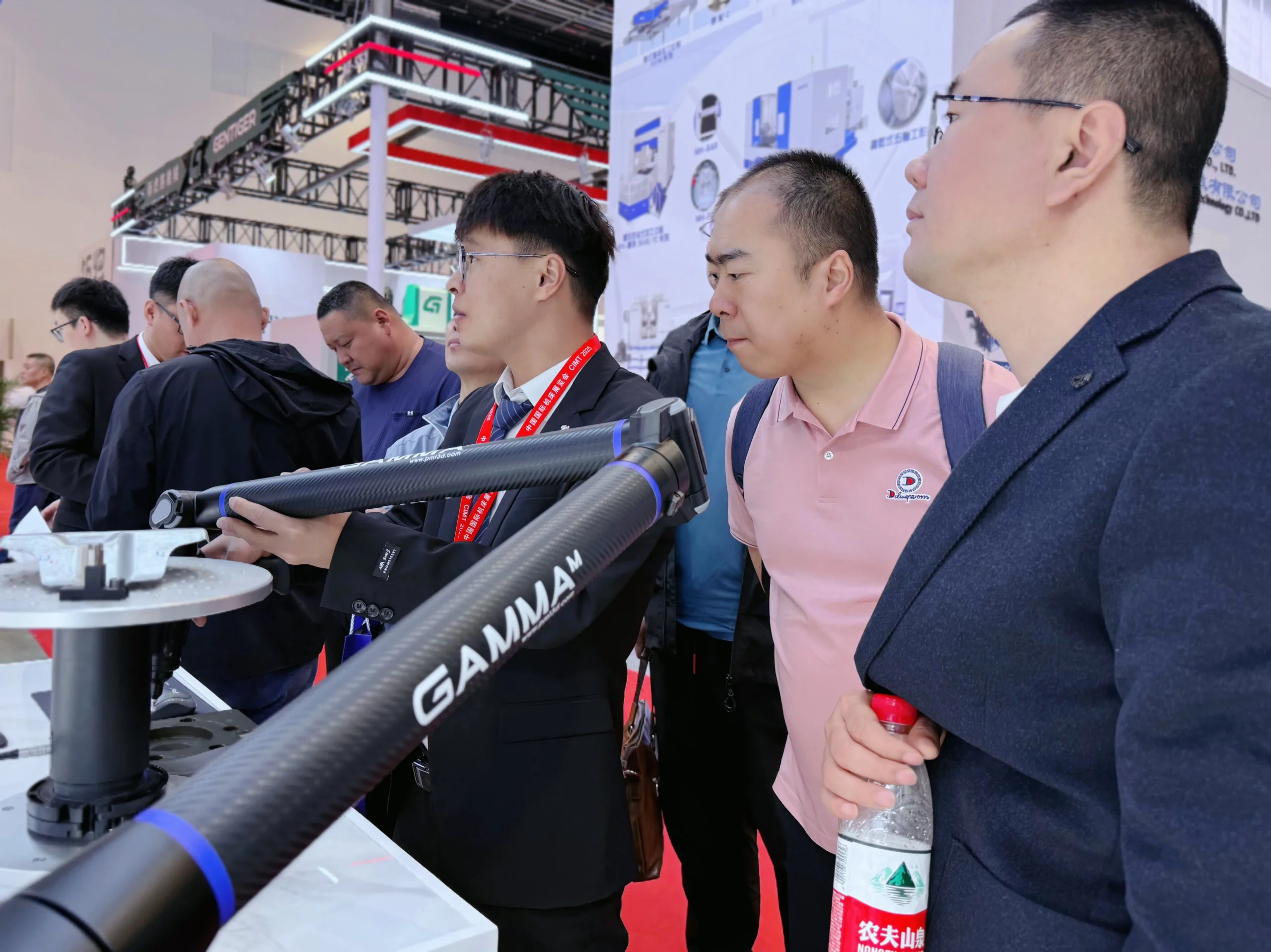

Attraction of Strategic Collaborations Worldwide

At the exhibition, PMT set dual records for detection accuracy and efficiency with its portable arm and CMM equipment, attracting great interest from top global machine tool manufacturers, component suppliers, and aerospace companies, which spanning high-growth industries such as precision machining, smart manufacturing, and semiconductor inspection.

Human-Centric Innovation | From Technological Breakthroughs to Workforce Empowerment

Comprehensive Solutions for Multiple Scenarios

To address customer pain points in high-precision inspection of complex workpieces, PMT launched a portable CMM with blue 3D arm scanner based on a 3D measurement software. With surface fitting accuracy as high as 0.035mm, data collection efficiency of the portable measuring arm improved by over 50% compared to traditional methods. Combined with an 8-axis rotary worktable, the inspection efficiency of the 3D measuring arm further increased by more than 40%.

Smart Manufacturing Practices

Designed for low power consumption and easy disassembly, PMT’s portable coordinate measuring machine significantly extends product lifecycle. The GAMMA arm CMM machine is also equipped with an adjustable laser brightness (4 levels) for eye-protection.

Dynamic Precision Compensation

PMT’s FUTURE and PRIME bridge Coordinate Measuring Machines feature advanced precision mechanical structures, motion control technology, data processing, and software algorithms. The real-time hardware-software data interaction showcased on-site, along with precise identification and efficient detection of the CMM machine, earned high recognition from technical teams of leading industry enterprises.

Global Vision|The Continuous Leap of Precision Measurement Technology

PMT will appear at the 37th CONTROL International Trade Fair for Quality Assurance in Stuttgart, Germany, from May 6-9. As a premier global event in the measurement instrument field, PMT will embark on a new journey with its full product line of portable arm, 3D scanning arm and CMM machine, accelerating the globalization of China’s precision measurement technology.

From groundbreaking innovations at CIMT to the global stage at CONTROL, PMT continues to push boundaries, innovate, and demonstrate excellence every step of the way. See you in Stuttgart!

The post Blockbuster News|Live from PMT at CIMT – Sneak Peek at CIMT Highlights! appeared first on PMT.

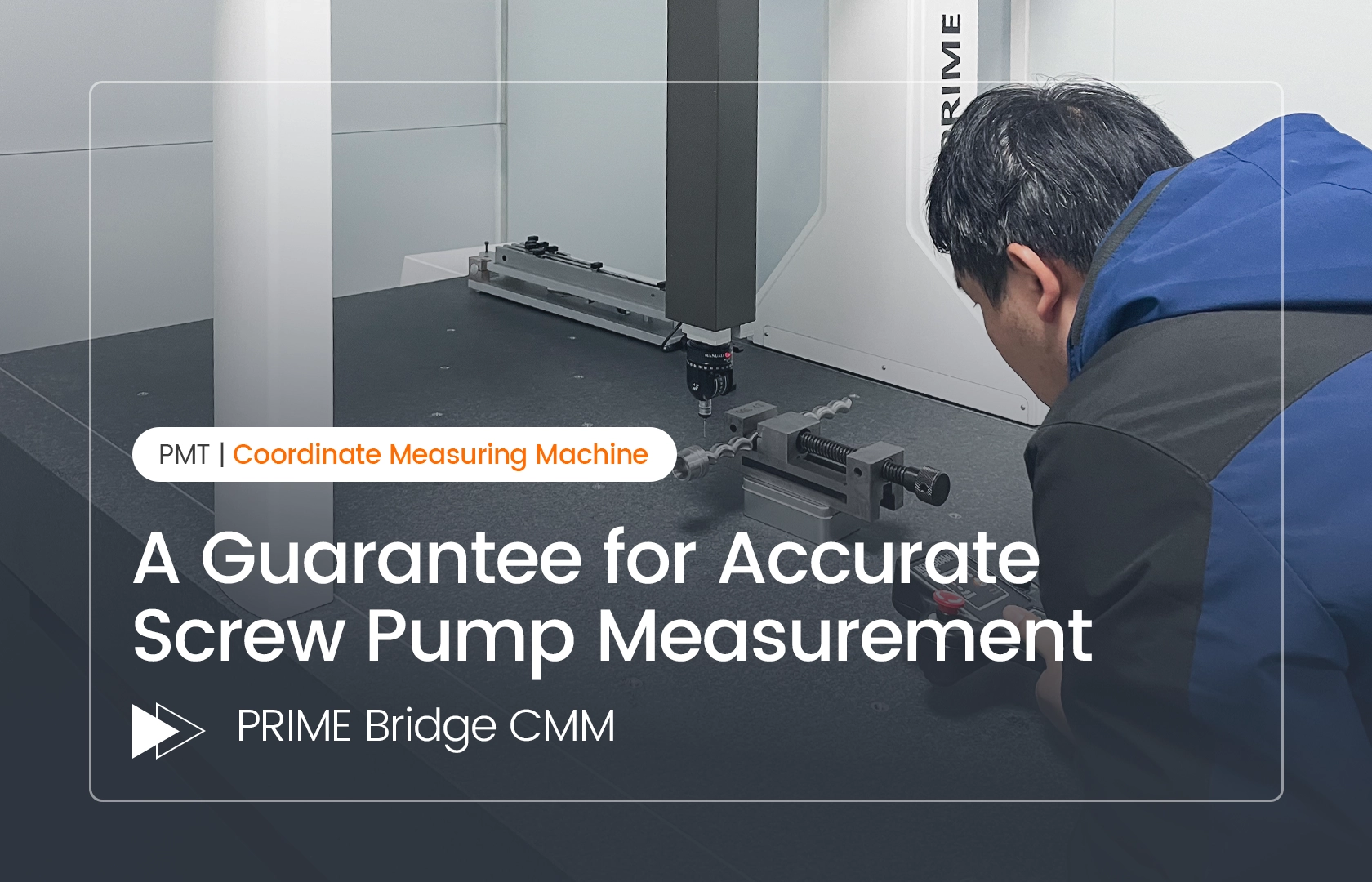

]]>The post PMT Coordinate Measuring Machine: A Guarantee for Accurate Screw Pump Measurement appeared first on PMT.

]]> In the application of coordinate measuring machine measurement, the spiral pump, also known as the Archimedes’ screw or water screw in the engineering machinery industry, is a screw that uses the rotation of blades to progressively moving fluid along the screw’s axle. Due to its unique structure and performance advantages, the screw pump has been widely used in various scenarios in the mechanical manufacturing field.

In the application of coordinate measuring machine measurement, the spiral pump, also known as the Archimedes’ screw or water screw in the engineering machinery industry, is a screw that uses the rotation of blades to progressively moving fluid along the screw’s axle. Due to its unique structure and performance advantages, the screw pump has been widely used in various scenarios in the mechanical manufacturing field.

Challenges in Screw Pump Precision Manufacturing

The performance of a screw pump is significantly influenced by the manufacturing precision of its key components, particularly the dimensions and gap of the screw. Below are the primary challenges encountered in the manufacturing process of screw pumps:

1.Dimension Requirements

①The outer diameter, pitch, lead, and other dimensions of the screw must be controlled within micrometer-level tolerance (usually ±0.01 to ±0.05mm).

②For double-screw or triple-screw pumps, the meshing gap between screws must be uniform (typically between 0.05 and 0.15mm). A large gap can lead to internal leakage, while a small gap may result in jamming or wear.

2.Consequences of Poor Precision

①Fluid Leakage: A large gap or deviation can cause the fluid to flow back from the high-pressure area to the low-pressure area, then reducing volumetric efficiency.

②Efficiency Decrease: Increased internal leakage and friction lead to higher energy consumption.

③Vibration and Noise: Uneven meshing or axis deviation can cause mechanical vibrations and noise.

④Wear Intensify: Surface roughness or insufficient hardness can shorten the screw’s lifespan, especially when transporting fluid containing particles.

⑤Jamming Risk: A small gap or uncompensated thermal expansion can lead to screw lock due to temperature changes.

PMT CMM Precision Measurement Solution

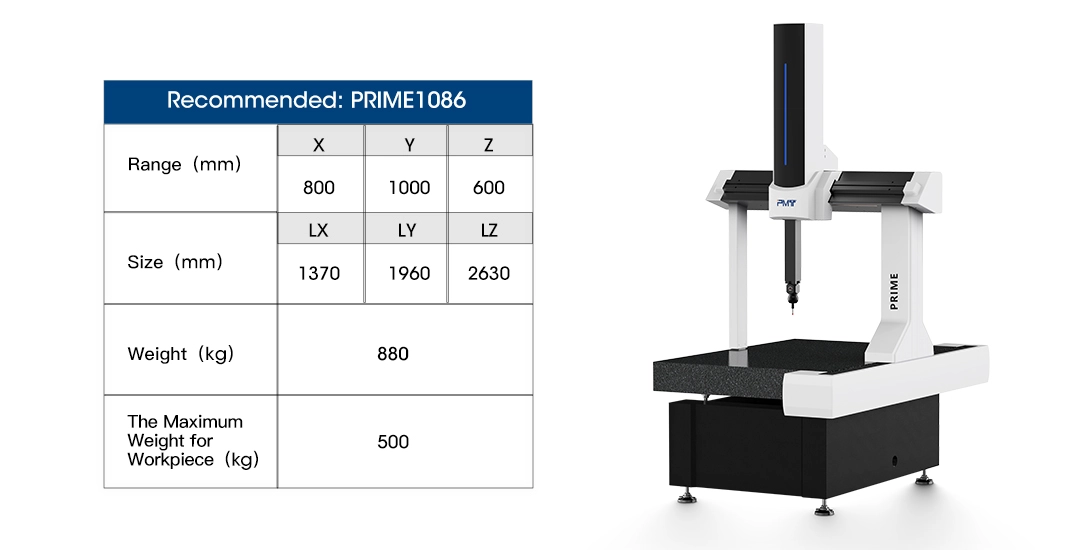

Recommended Configuration

Measurement Range: 800*100*600mm, which can meet the measurement needs for most of screw pump parts.

Probe Head: MH20i, a manual articulating probe head kit, easy to operate and highly adaptable.

Stylus: D4*L20, which is suitable for measuring a variety of materials and shapes.

Measurement Angles: A0B0, A90B90, A90B-90, ensuring the accuracy of measurement results.

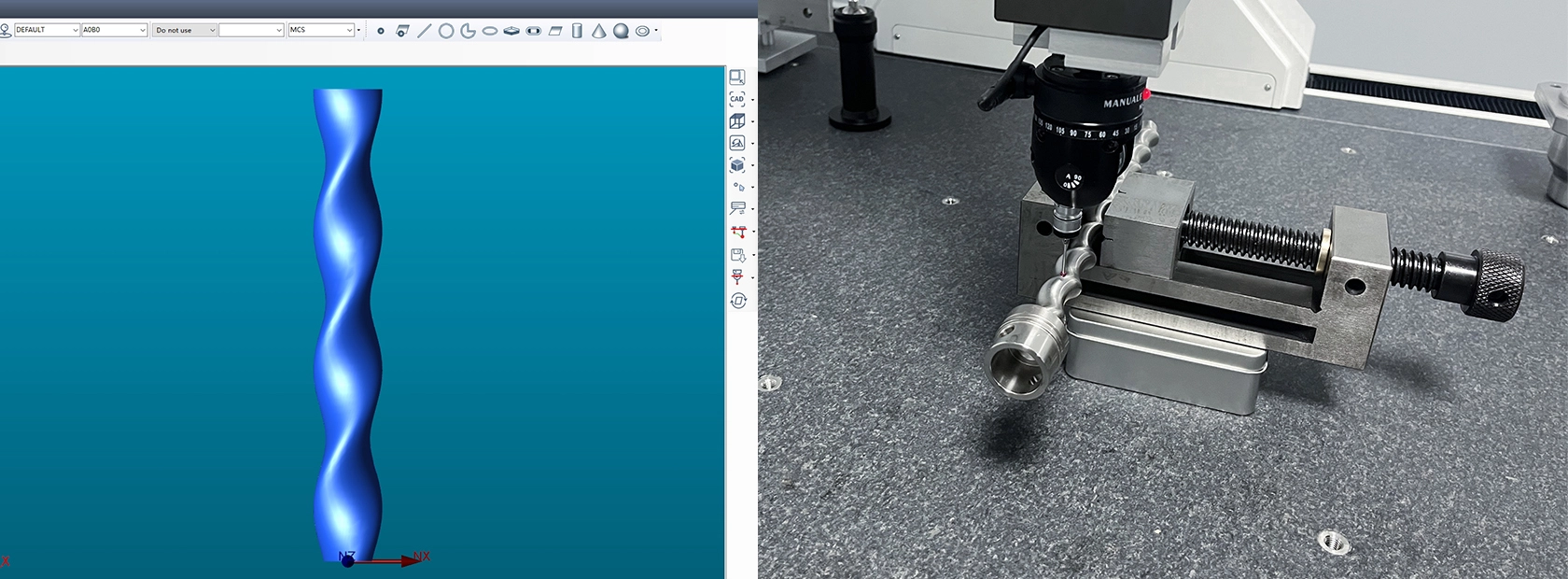

Measurement Process

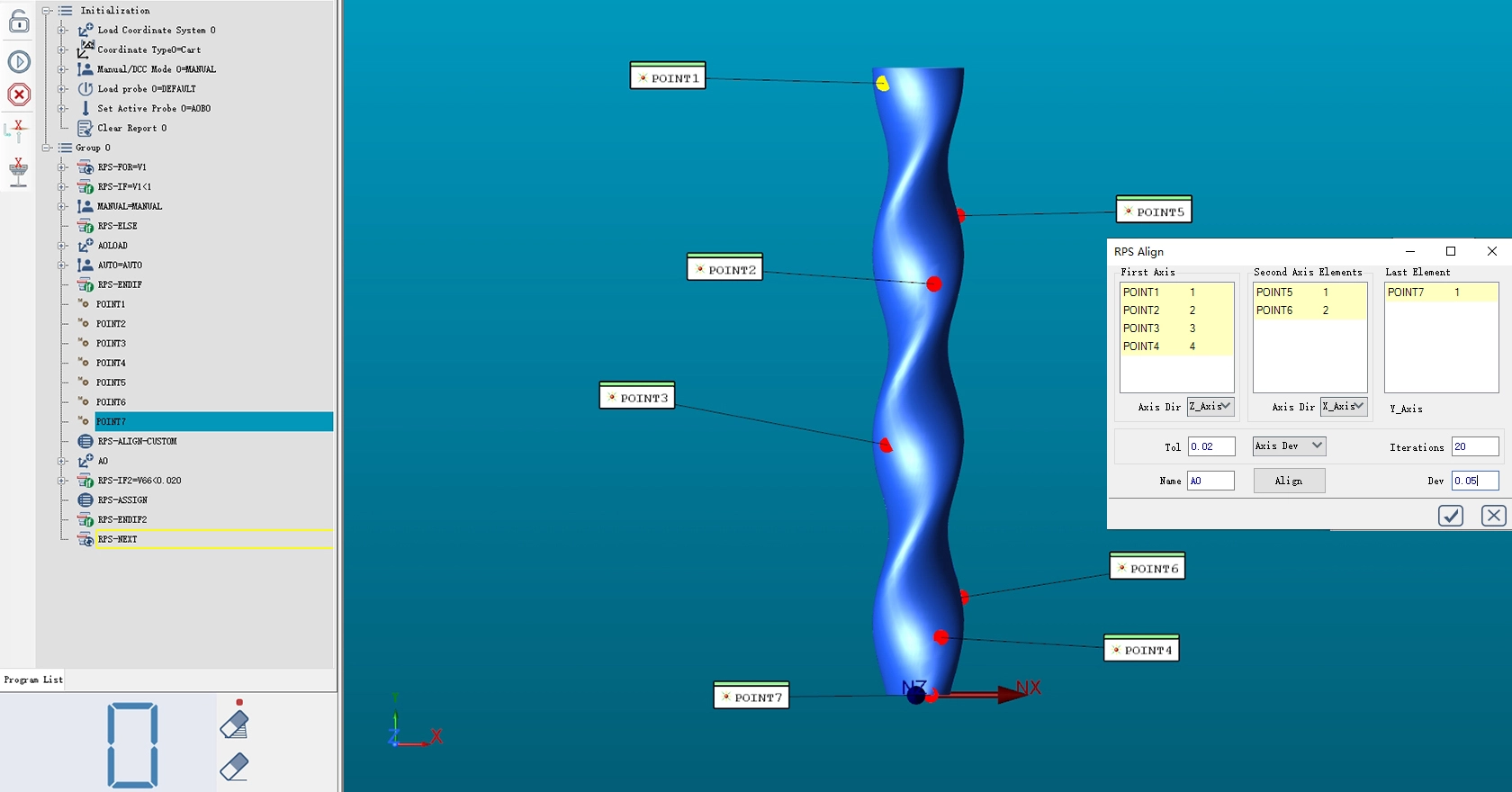

1.Import the CAD Model: Import the CAD model into the measurement software to establish a datum for subsequent measurements.

2.Establish the Coordinate System: Use the iterative method to select the point-controlled axis and set the maximum number of iterations and iteration deviation to ensure the accuracy of the coordinate system.

3.Manual Measurement: Manually measure key points, with the software automatically iterating and optimizing to obtain the best values.

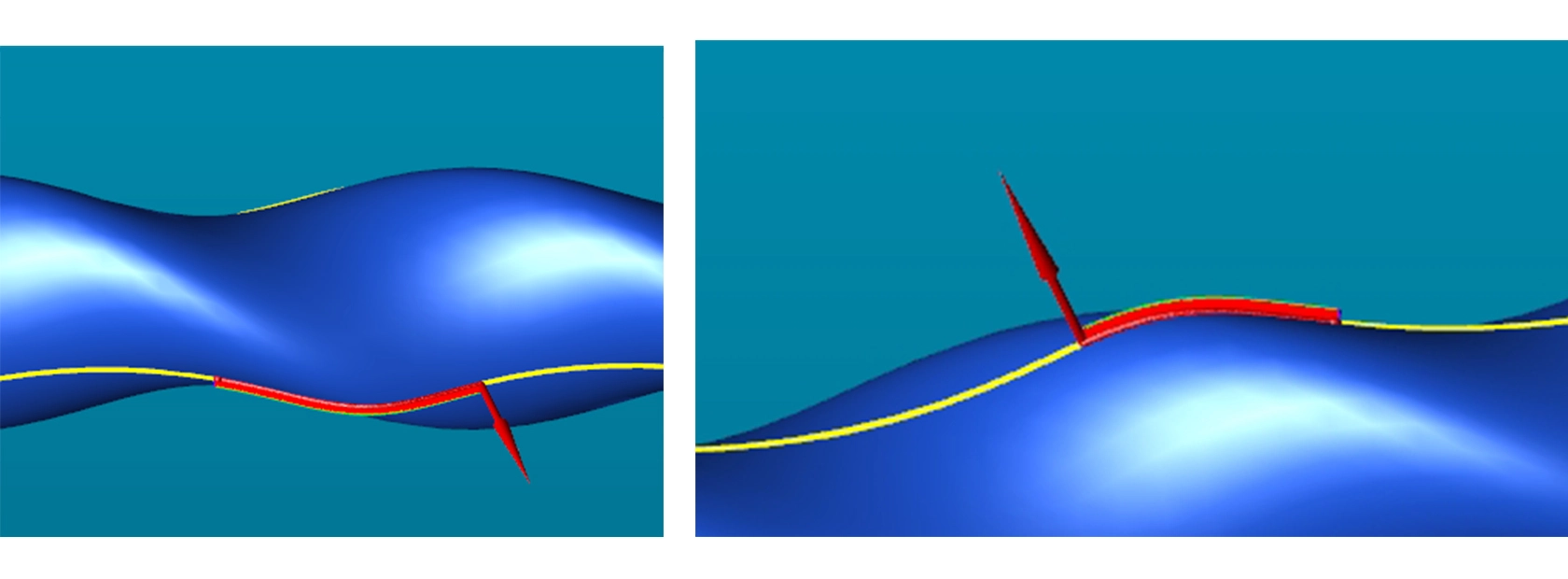

4.Section Scanning: Use the section scanning function to measure the screw’s surface profile to ensure its accuracy.

5.Construction and Evaluation: Use the construction function to extract the apex of surface and evaluate the outer/inner diameter distances to ensure the dimensions meet design requirements.

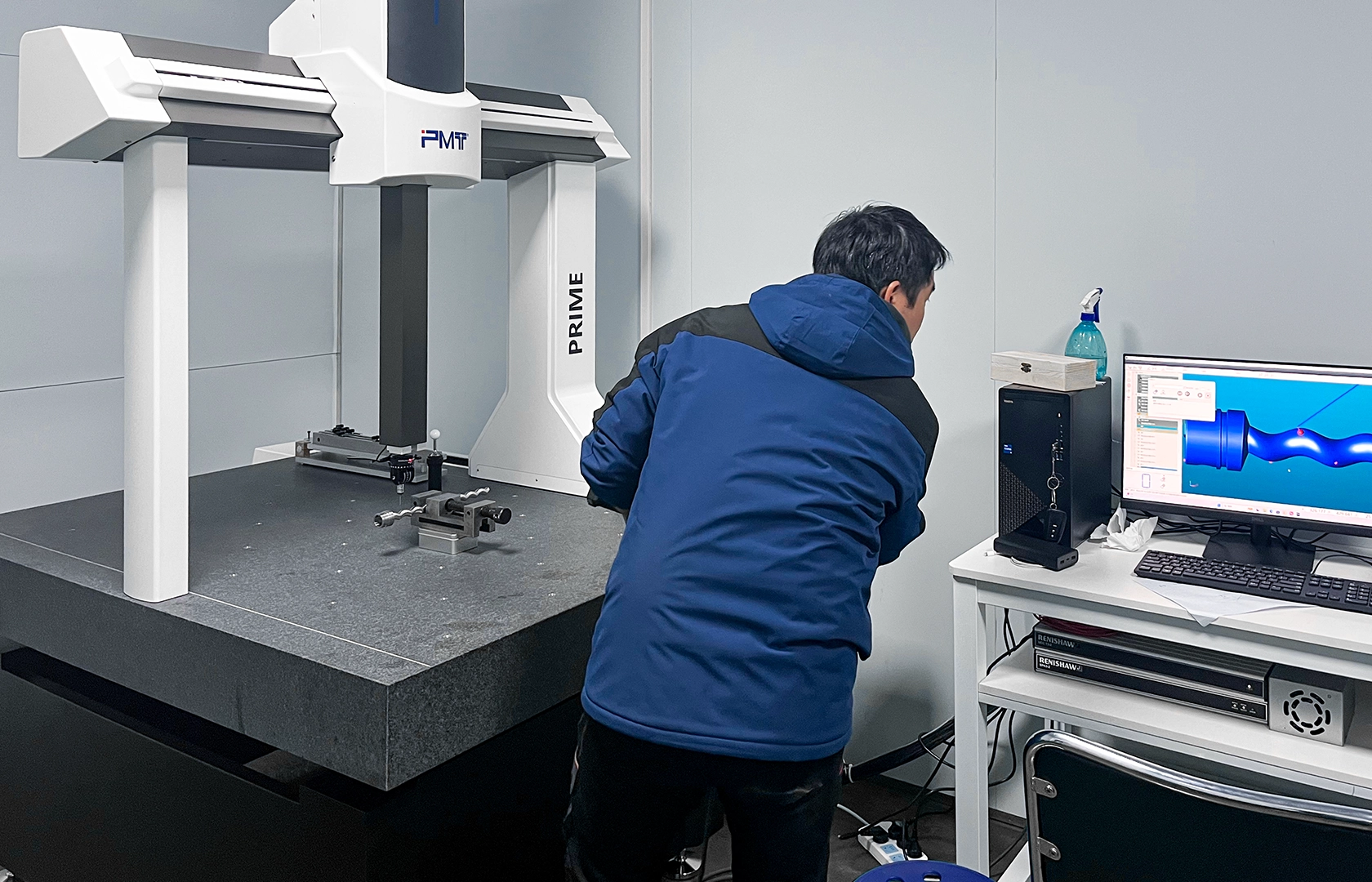

Core Advantages of PMT PRIME Coordinate Measuring Machine

The PMT PRIME Coordinate Measuring Machine stands out as the ideal choice for screw pump manufacturing industries owing to the following core advantages:

1.High-Precision Measurement: PMT CMMs meet the micrometer-level tolerance requirements of screw pumps, ensuring product quality.

2.High-Efficiency Measurement: PMT CMMs’ automated measurement processes significantly enhance inspection efficiency.

3.Professional Support: PMT CMMs provide a one-stop service from equipment selection to measurement solution design.

4.Wide Applicability: PMT CMMs are suitable for measuring a variety of precision parts, including screw pumps, semiconductor equipment, etc.

Conclusion

As a critical equipment in the fluid transport field, the performance of a screw pump is closely bound up with its manufacturing precision. The PMT PRIME CMM provides reliable measurement solutions that are widely applicable within the screw pump industry. What’s more, the PMT coordinate measuring machines have empowered enterprises to continuously improve product quality and enhance production efficiency.

The post PMT Coordinate Measuring Machine: A Guarantee for Accurate Screw Pump Measurement appeared first on PMT.

]]>The post PMT Technologies | PMT Strengthens Overseas Technical Support appeared first on PMT.

]]>

From February 17 to 19, 2025, PMT hosted a technical exchange with its European partners. They are Aitor López from Spain, Eduard Vulcan from Romania, and Marco Zancanaro from Italy. PMT’s technical team collaborated with these industry experts to deliver special training and workshops on systematic maintenance and high-precision calibration for portable CMMs and coordinate measuring machines (CMMs).

During the three-day immersive program, under the guidance of senior maintenance engineer Craig, our partners gained hands-on expertise in modular repair techniques, calibration for PMT’s articulated arm CMMs and scanning heads, as well as precision debugging techniques for CMMs. The training, which combined theory and hands-on practice, enabled the participants to master comprehensive maintenance and better understand the application in real-world scenarios.

Paolo, PMT’s European Regional Director, has been a driving force behind the global expansion of the company’s products and services. During the event, Paolo invited Italian partner Marco to tour PMT’s manufacturing base for CMMs. The visit highlighted core components of coordinate measuring machines, including precision debugging processes, metrology certification standards, and cutting-edge calibration algorithm applications.

“Measurement knows no borders, and service knows no limits,” said Enoch, PMT’s Technical Service Director. “This exchange combined theoretical instruction, hands-on practice, and case study in a multi-dimensional training model. It significantly elevated our partners’ technical proficiency. We will continue refining our global technical service system to ensure standardized and professional local support for every client and laying a solid foundation for deeper international collaboration,” he added. By integrating portable measuring arms and CMM machine technologies into its global framework, PMT remains committed to advancing sustainable innovation and cross-border technical empowerment.

The post PMT Technologies | PMT Strengthens Overseas Technical Support appeared first on PMT.

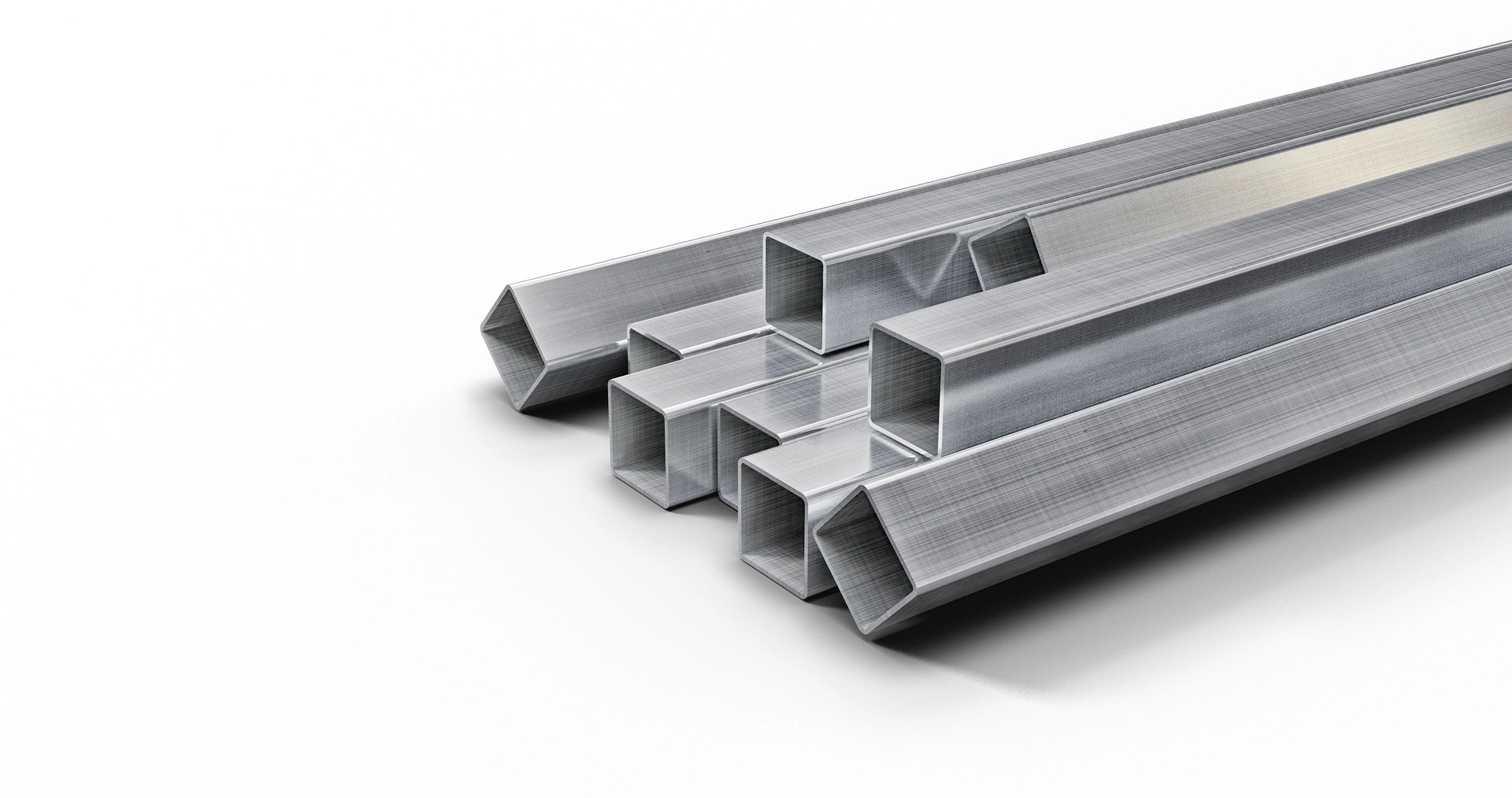

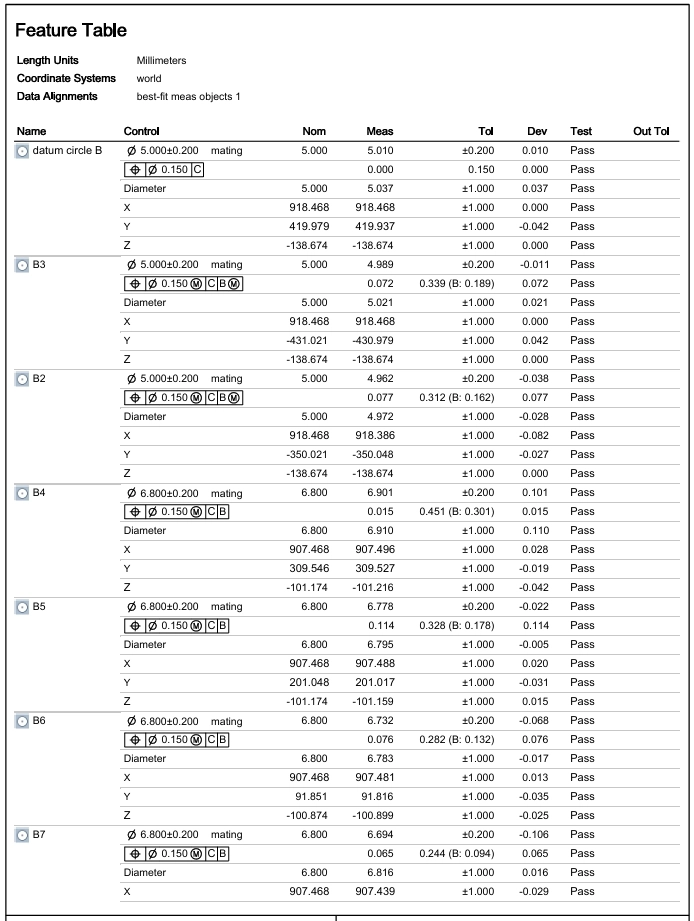

]]>The post PMT Portable Measuring Arm Provides Guarantees for the Quality of Sheet Metal Square Pipe Fittings appeared first on PMT.

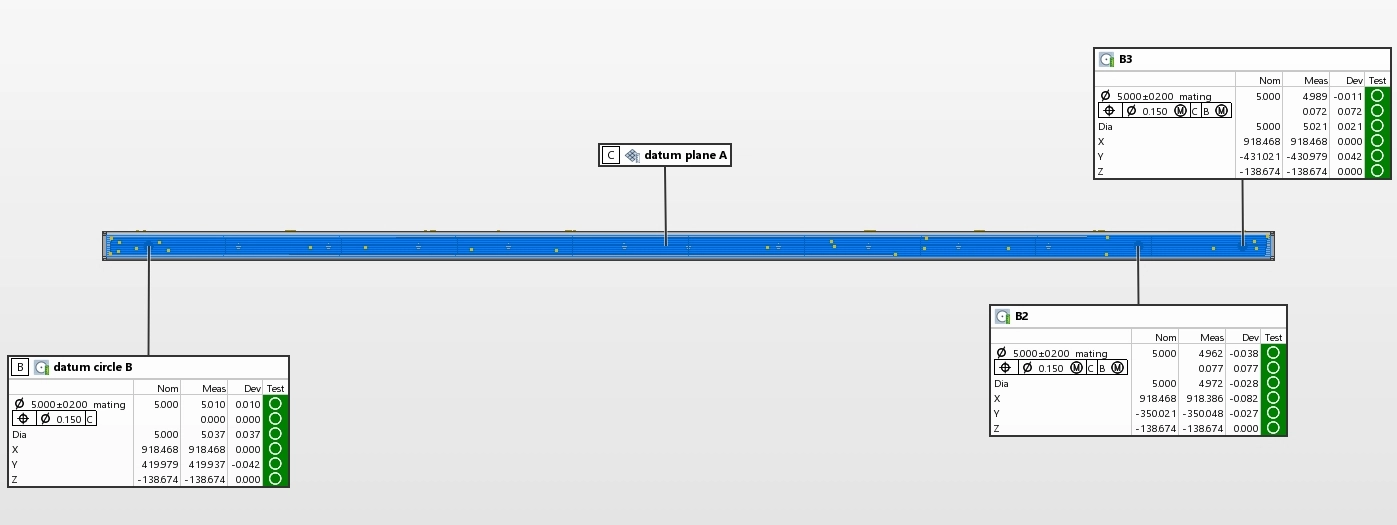

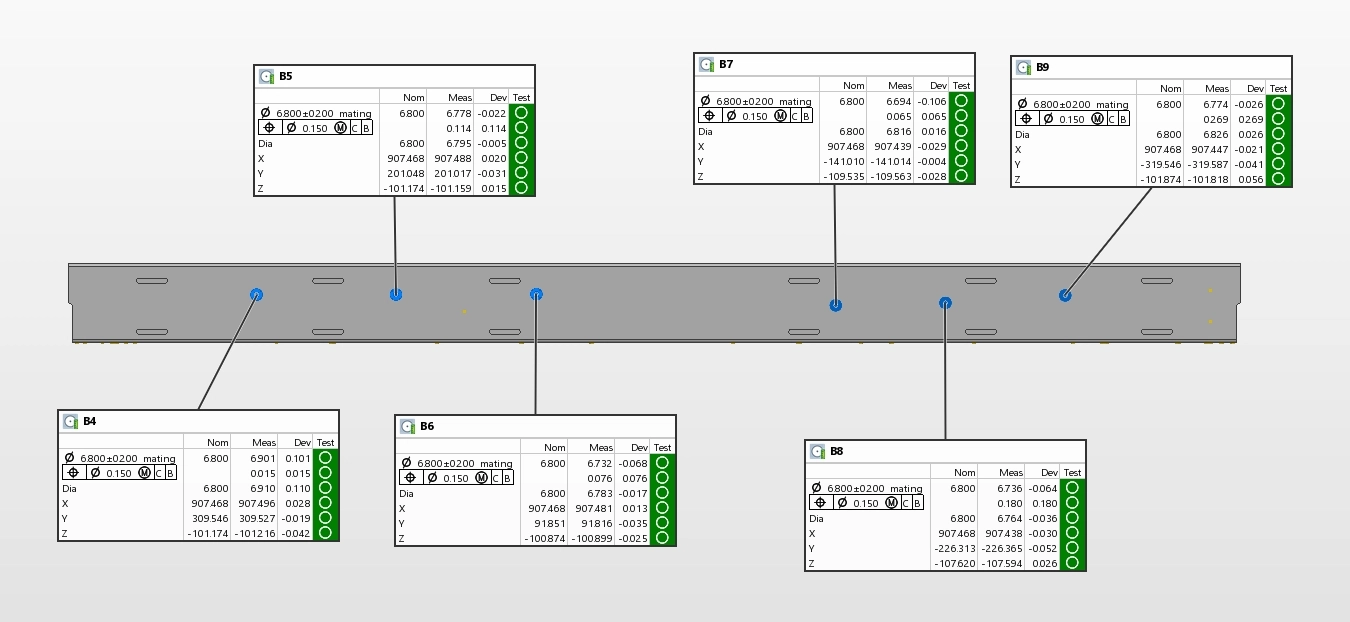

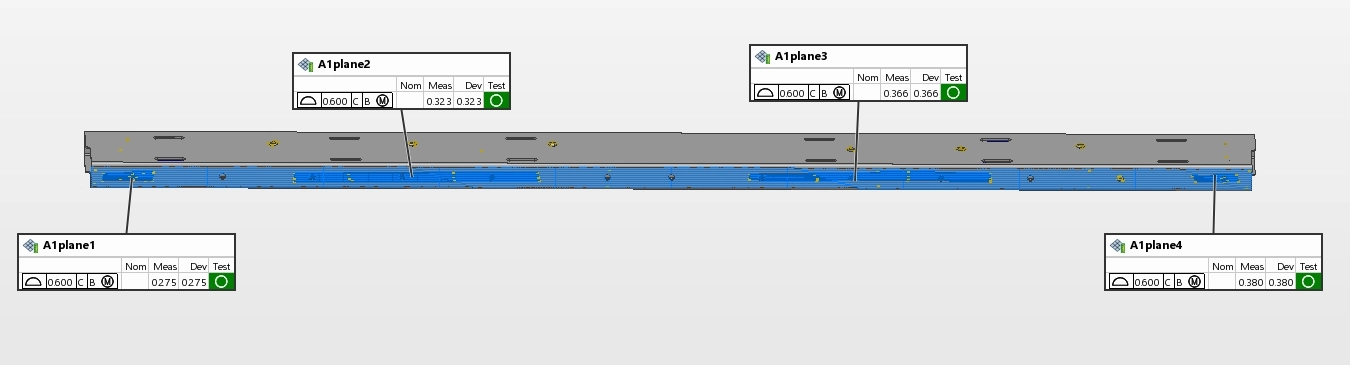

]]>Measureing? Challenges

- When measuring the wall thickness of small-sized sheet metal square tubing, traditional measuring tools often fail to meet the required precision, and human errors easily occur.

- Traditional methods only provide static data and are unable to monitor the changes of the fitting sizes in real-time or detect quality issues during the production process.

Recommended Solution

1) Measurement Principle

When measuring square tubing, the operator needs to hold the portable arm and touch the probe on the surface of the measured target. By rotating and moving the elbow, the arm is able to collect coordinate data from different positions on the tubing. Then, the data will be transmitted to the control system and processed and analyzed by the software. Finally we get the required dimensions, shapes, and positions of the tubing.

2) Measurement Steps

- Establish the Coordinate System

① Compare the workpiece with the drawings. Analyze the drawing requirements and relations between each dimension, and identify the features on the workpiece. Use the measuring arm to detect the relevant feature elements.

② Import the CAD model. After importing the CAD model, the PMT engineer will delete unnecessary components (such as cylinders, connecting blocks, valve islands, brackets, screws, etc.) according to the requirements of the CAD model, and retain the modules that need to be inspected.

③ Establish the coordinate system (usually using methods such as the center point of the plane axis, iteration, etc.). Align the measured data with the nominal data to establish the positional relationship between the measuring arm and the workpiece. This will facilitate the next steps.

- Data Acquisition

Contact measurement with the portable measuring arm: The engineer will collect data by touching the surface of the workpiece with the ball probe of the arm and use the least squares method to best-fit the measured data parameters.

- Data Analysis

Based on the technical requirements, we can analyze the position of holes and surfaces. In the measurement system, the shape deviations, position and other parameters of the measured object can be evaluated, and the key dimensions can be marked.

- Report Generation

Generate a report based on the measurement results. The report should include basic information about the measured object, parameters, results, error analysis, and other relevant content.

- Feedback of Results

Send the measurement results to relevant departments so the company can facilitate subsequent production, processing, and quality control activities.

- Batch Inspection

Since sheet metal components are often mass-produced, it is common to conduct random sampling or batch inspection of the same product. In such cases, the creation of new workpiece command in the software can be used for repeated inspections, with no need for data editing or processing, greatly improving measurement efficiency.

Advantages of the Portable Measuring Arm in Pipe Fitting Inspection

① High Precision

The PMT portable arm employs advanced angle encoder technology, enabling high-precision measurements that meet the requirements of most industrial production and quality inspection processes.

② High Efficiency

Compared to traditional methods, the PMT measuring arm is easy to install and calibrate. Operators can quickly learn how to use the machine, an process and analyze the data through the software, reducing the workload associated with manual calculations and data handling, thereby increasing work efficiency.

③ Strong Flexibility

The PMT portable measuring arm can rotate and move flexibly, adapting to the measurement needs of square tubing of various shapes and sizes. It can also be used in complex environments.

Other Applications

In industries such as mechanical manufacturing, automotive manufacturing, and aerospace, square tubing is widely used in the production of various structural components. For large square tubing structures, such as steel structures in construction or bridge structures, the PMT measuring arm is able to perform rapid on-site inspection to ensure construction quality control.

During the research and development of square tubing, the PMT portable arm can provide precise measurements of samples to optimize the design process. It can also compare different schemes and select the optimal design for customers.

Conclusion

The PMT portable measuring arm is the ideal tool for measuring sheet metal square tubing. With its high precision, high efficiency, and strong adaptability, it meets the high demands of industrial manufacturing, provides reliable quality assurance, and plays an important role in the research and development stage, showing great value across different industries.

The post PMT Portable Measuring Arm Provides Guarantees for the Quality of Sheet Metal Square Pipe Fittings appeared first on PMT.

]]>The post A Powerful Tool to Help Deliver Improved Quality in the Automotive Industry appeared first on PMT.

]]>Price war has become the norm since the rapid development of the market will inevitably bring fierce competition. However, the market has proved that car companies have been raising their competitiveness, and the trend has shifted from low-priced competition to applications of cutting-edge technologies, exceptional performance of products, and branding development. This will help reshape the industry.

3D measurement technology has been playing an increasingly important role in modern manufacturing. It can provide high-precision measurements for different sizes and shapes, which is of great significance for improving product quality and production efficiency. As an advanced 3D geometric measurement system, PMT ALPHA has a built-in counterbalance system which is specially designed for on-site inspection. The structure of the equipment is simple and balanced, thanks to its perfect equal arm length design, which delivers an outstanding arm-operating experience. PMT portable arm is compatible with many measurement software and widely used in manufacturing industries as follows.

Reverse Engineering

In scanning clay sculptures or similar kinds, the Alpha M ScanArm can quickly model with its collected data without pasting marking points, which greatly shortens the design cycle and thus improves efficiency. Here is an example from a car manufacturer who used reverse engineering to do 3D modeling of a prototype car during the process of creating a new model. It all only took two weeks, saving about 40 percent of the time compared with traditional methods.

Molds and Production Tools Inspection

Use ALPHA Arm to do regular inspection of molds and production tools, and to analyze the wear condition so repairs or replacement could be made. For example, the customer used the PMT Alpha arm on their auto parts production line to inspect the mold on a regular basis. They detected and fixed a slight wear problem in time, helping prevent production delays and cost increases caused by mold damage.

CAD Model Comparison

Using ALPHA Arm to measure 3D coordinates will help ensure the accuracy of auto parts. We can see deviations between the actual workpiece and the CAD model by comparing the measured data with the nominal data. For example, in a process of quality control of key components, the operator used the ALPHA arm to detect dimensional deviations in a batch of components, and feedback was immediately sent to the production department. It effectively helped prevent the customer from producing batches of substandard products.

Tool Alignment

We can make adjustments to the assembly position according to the obtained accurate data of the auto parts so as to make sure the accuracy and quality of the whole process. For example, on the assembly line of a high-end model, the application of the PMT ALPHA arm has improved the assembly accuracy by 20 percent, significantly enhancing the quality of the vehicle and customer satisfaction.

The post A Powerful Tool to Help Deliver Improved Quality in the Automotive Industry appeared first on PMT.

]]>The post PMT South China Solution Center Unveils Strategic Upgrade to Empower Regional Manufacturing appeared first on PMT.

]]>The launch of the center marks a pivotal step in PMT’s commitment to enhancing regional service capabilities and expanding technological applications. It will deliver efficient, precise, and localized technical support to clients across South China.

Focusing on Needs, Empowering with Technology

Centered on “On-site technical demonstrations”, the South China Solution Center is equipped with cutting-edge tools such as CMM machine, portable measuring arm, and a team of expert engineers. These resources enable rapid responses to measurement demands in automotive manufacturing, precision electronics, mold development, and other industries. Through hands-on guidance and real-time problem-solving, PMT aims to help clients experience firsthand how high-precision measurement technologies optimize production efficiency while delivering customized solutions tailored to regional needs.

Collaborative Innovation, Elevated Services

Leveraging the National Mold Center’s industry-leading expertise and PMT’s more than 20 years of technical prowess in precision measurement, the partnership will drive collaborative initiatives such as technical training, process optimization, and R&D projects to accelerate South China’s transition toward intelligent manufacturing.

The center has now opened for visits and technical exchanges, offering clients seamless access to PMT’s expertise.

Moving forward, PMT will continue to innovate and strengthen synergies with regional industry partners. By providing end-to-end services spanning measurement equipment, technical consulting, and talent development, the South China Solution Center will serve as a cornerstone for advancing high-quality growth in China’s measurement industry.

The post PMT South China Solution Center Unveils Strategic Upgrade to Empower Regional Manufacturing appeared first on PMT.

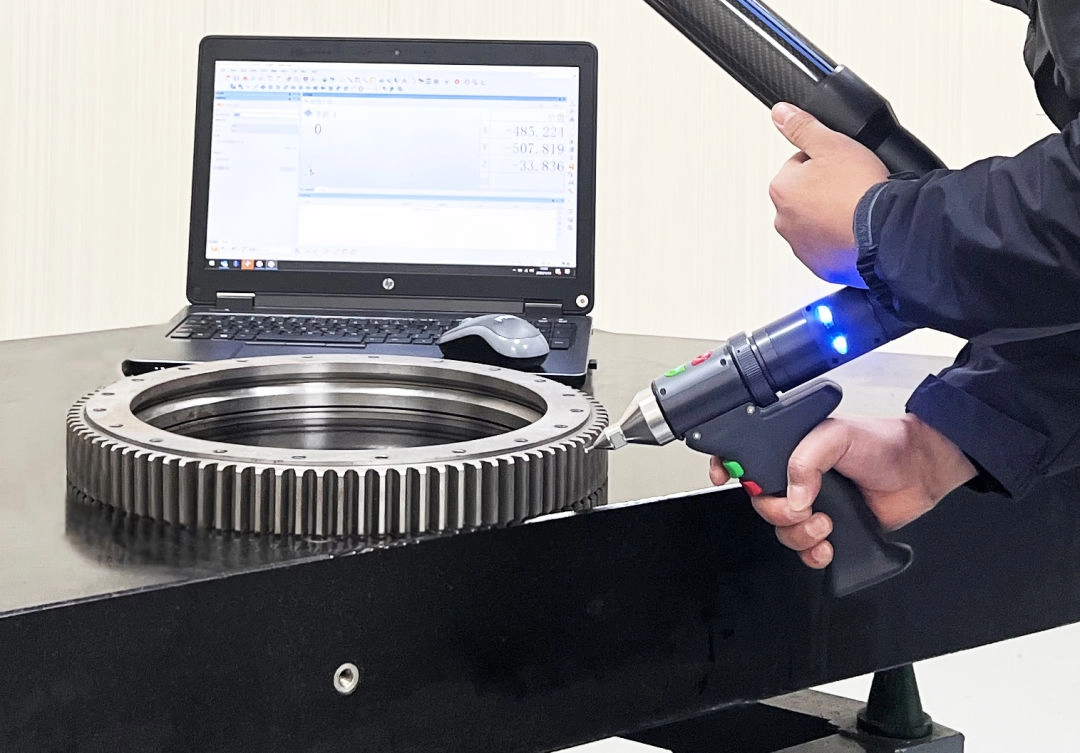

]]>The post PMT’s Measurement Solutions Shine in the Gear Industry appeared first on PMT.

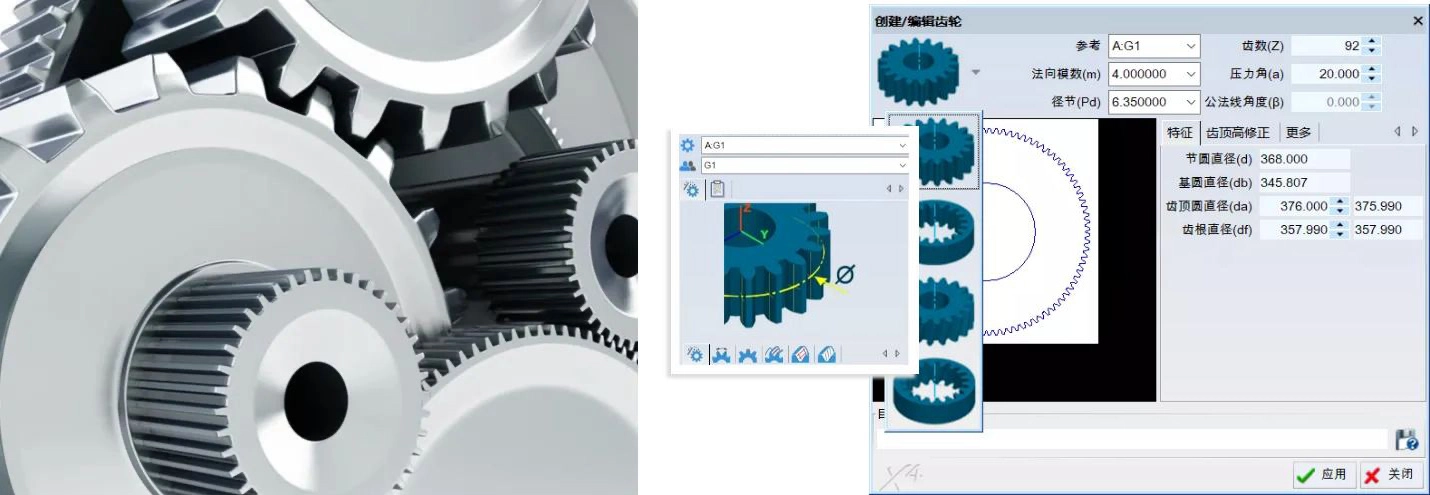

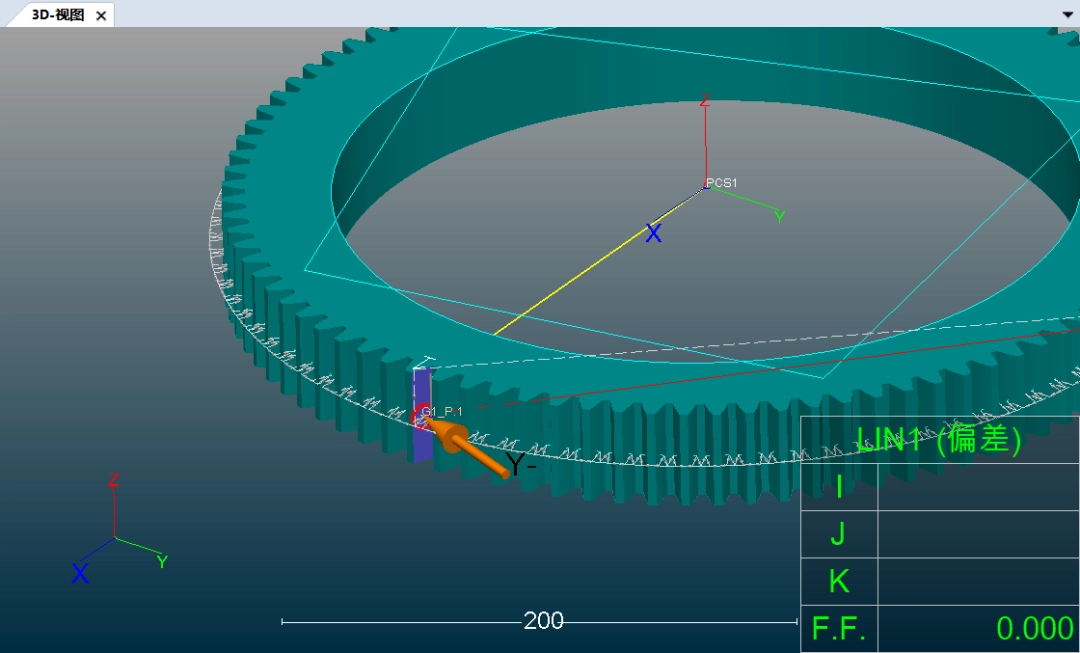

]]>

Challenges

Gear is the key component of many industrial equipment. To meet high precision demand in technical parameters, size and quality, the problems in choosing suitable measurement solutions and machining methods have drawn our attention. In addition, due to the influence of geometric size and mechanical properties, the difficulties of measurement in large gears are much greater than that in small medium ones.

To solve the problem, PMT ALPHA ARM, by virtue of its operational ease for use and portability, can realize the high accuracy measurement of large-sized gears and gives good precision.

Gear Inspection Analysis

There are many factors that lead to bad gear accuracy, such as machining errors and tool errors. PMT ALPHA ARM supports online inspection for different gears by creating coordinate systems and generating professional reports.

Define Gears

According to the parameters in the process drawings, choose a Gear type in the Create dialog box, setting the parameters and a CAD model is displayed in the 3D scene automatically.

Alignment

Different serial numbers are designated to each tooth of the gear through alignment in the software, in this case we use Plane-Axis-Point Alignment approach to create coordinate system. After coordinate system is established, the measuring program and path are automatically presented in the software. We can follow the arrow to finish the inspection.

Generate Report

We can generate a professional gear report when inspection is finished.

On-site Application

Gear has complex shapes. In the field measurement, it is regarded as a geometric entity to realize functions of transmission based on the whole theory error, and elementary geometrical errors can be measured through the coordinate analytical geometry method.

Multiple Installation Modes

PMT ALPHA ARM provides multiple installation modes to meet diversified demands on site, for example, circular disc integrated magnetic mount, electric vacuum clamping plate, and folding adjustable tripod. The magnetic mount features strong magnetic force and occupies less space, with which the equipment can be firmly mounted to the piece surface for easier inspection.

Fully-enclosed Structure and High-speed Wifi Performance

Thanks to its fully-enclosed structure, PMT ALPHA ARM can respond to different temperatures, humidity and multi-dust environment. The portable measuring arm can offer a smooth wireless connection and is an ideal equipment for messy and crowded workshops.

Equal-length Arm Design

The equal-length arm is designed to achieve a full-scale measurement through investing a stable equilibrium when probing positions near the base.

Intelligent Temperature Compensation System

To avoid interference from different temperatures, PMT ALPHA ARM integrates high-precision temperature sensors in each axis that can compensate errors in real time and ensure accuracy consistency in online inspection.

“The first time I used PMT portable arm to measure gears, it was very light and easier than expected. And most of our inspection work can be completed by it very quickly without finding other measuring tools everywhere. We’ve been using it for a while and felt it is much more convenient than the previous tools. We are so excited to have this portable equipment to measure our products,” said a surveyor in a gear company.

Looking back, people have been seeking for measurement solutions for gears for nearly 100 years. Looking forward, advanced measurement technology will inevitably play an important role in gear manufacturing. To this end, with a focus on the field of portable measurement, PMT will continue to refine, enrich, update and improve its technologies so that it will provide more effective technical means to enhance the core competitiveness of gear production. In this way, PMT will promote the transformation and upgrading, and deepen the development of the gear manufacturing industry.

The post PMT’s Measurement Solutions Shine in the Gear Industry appeared first on PMT.

]]>