Ticon Precision Machinery (Wuxi) Co.,Ltd. is primarily engaged in the precise cutting and machining of aluminum alloy products, enjoying a considerable market share in the aerospace and semiconductor domains. Additionally, it serves as a certified supplier for renowned Japanese enterprises such as Hitachi and Toshiba. The headquarters of Ticon Precision Machinery is situated in Aichi Prefecture, Japan, and its first overseas factory was founded in Wuxi Huishan Economic Development Zone. This marked the start of its development in China, added new brilliance to the manufacturing sector of the development zone, and will further raise the level of the equipment manufacturing industry in the development zone and promote the expansion and strengthening of the equipment manufacturing industry.

The precision of machine parts nearly determines the quality of the product. The more precise a machine part is, the higher the precision required, and the more crucial quality becomes in the context of intensifying competition among domestic suppliers.

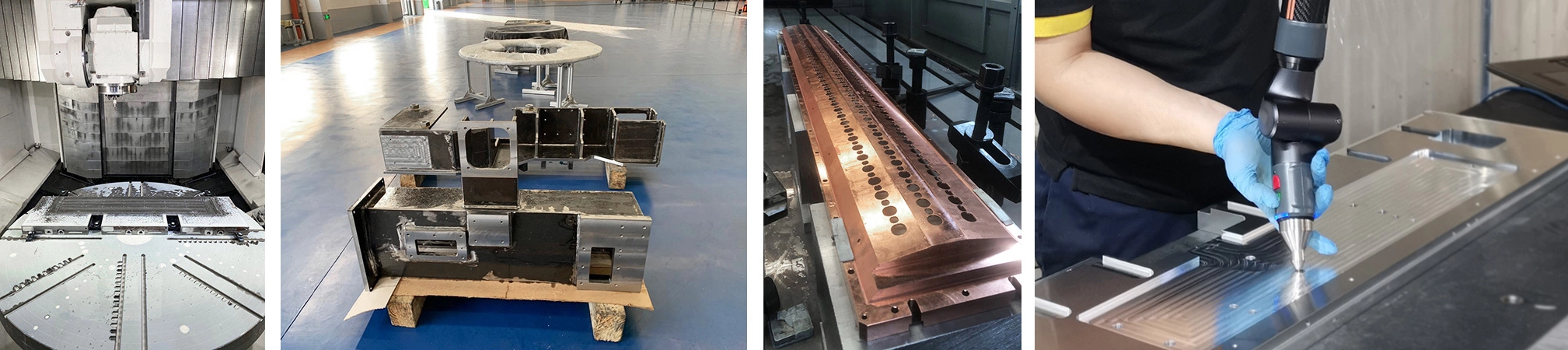

As the client is committed to the domains of aerospace, shipbuilding, semiconductors and FPD, specializing in non-standard manufacturing and proficient in the processing and welding of large and ultra-precision components, which production process admits of no errors. Nevertheless, the team in China has long relied on vernier calipers and micrometers for the majority of its measurements, which significantly fails to meet its requirements and cannot ensure accuracy. Furthermore, manual tools have their constraints. The size range of metal components spans from small parts approximately 10 x 10cm to larger structures 3 x 3m. Technicians in charge of measuring large structures typically take a full day to finish the work. Even then, the accuracy of the measurements largely hinges on the capability of each technician. Even with the most adept operators, measurements can sometimes be imprecise, and there are even dead ends that cannot be measured, compelling the team to postpone the project schedule.

Ticon China realized this and has been searching for suitable measurement equipment to meet its measurement needs in the market. Initially, General Manager Nakamura Shinya, who had been based in the Japanese headquarters for a long time, was more inclined towards a certain brand of portable measuring arm due to his knowledge of its use at the headquarters. However, in order to better understand the Chinese market, they learned about the performance advantages of PMT Arm through various channels and locked in our ALPHA P series, which opened the door to cooperation.

Quality and Efficiency

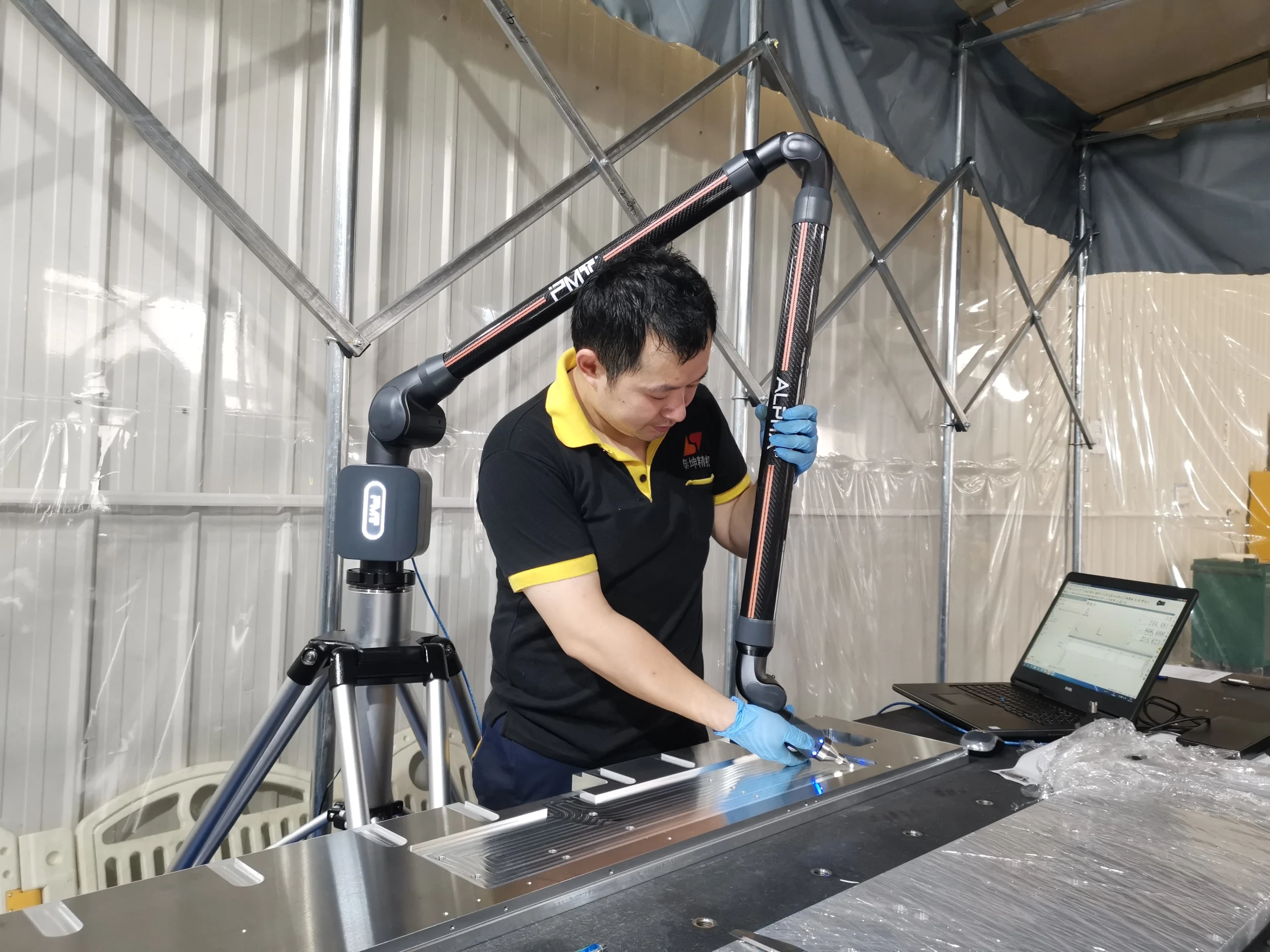

The ease of operating the PMT-Arm greatly enhances the work efficiency. Its intuitive design makes it easy for technicians to use and reduces the need to switch between several traditional tools. The precision of measurements also becomes more consistent, reducing the valuable time spent training new technicians. PMT sends a professional demonstration engineer to provide training after delivery, and customers can operate the measurement themselves in just 3 days.

Choose PMT

The General Manager of Ticon Nakamura Shinwa told us: Ticon is growing, and they need a portable measurement device that can be transported and used for on-the-spot measurements. The PMT Arm is not only portable for transportation, but also uses dual battery power, with each block lasting for more than 16 hours, providing enough power for two to three days of measurement work. In terms of transmission, it can not only be transmitted via USB, but also has a WIFI transmission interface, allowing for network function that enables multi-device management and monitoring within a company from any corner. The universal quick-installation base can be conveniently placed on any metal or granite surface, allowing us to make full use of the measurement arm.

Nakamura Shinwa believes that, through a comprehensive comparison, the PMT Arm is superior to the measurement equipment previously used by the Japanese headquarters and ultimately chose PMT.

We firmly believe that PMT Arm not only brings customers efficient and convenient solutions, but also brings new opportunities for growth and development. In the future, PMT will strive to meet customer needs by continuously upgrading production processes and technologies, maintaining the best partnerships, and opening up new possibilities for cooperation.