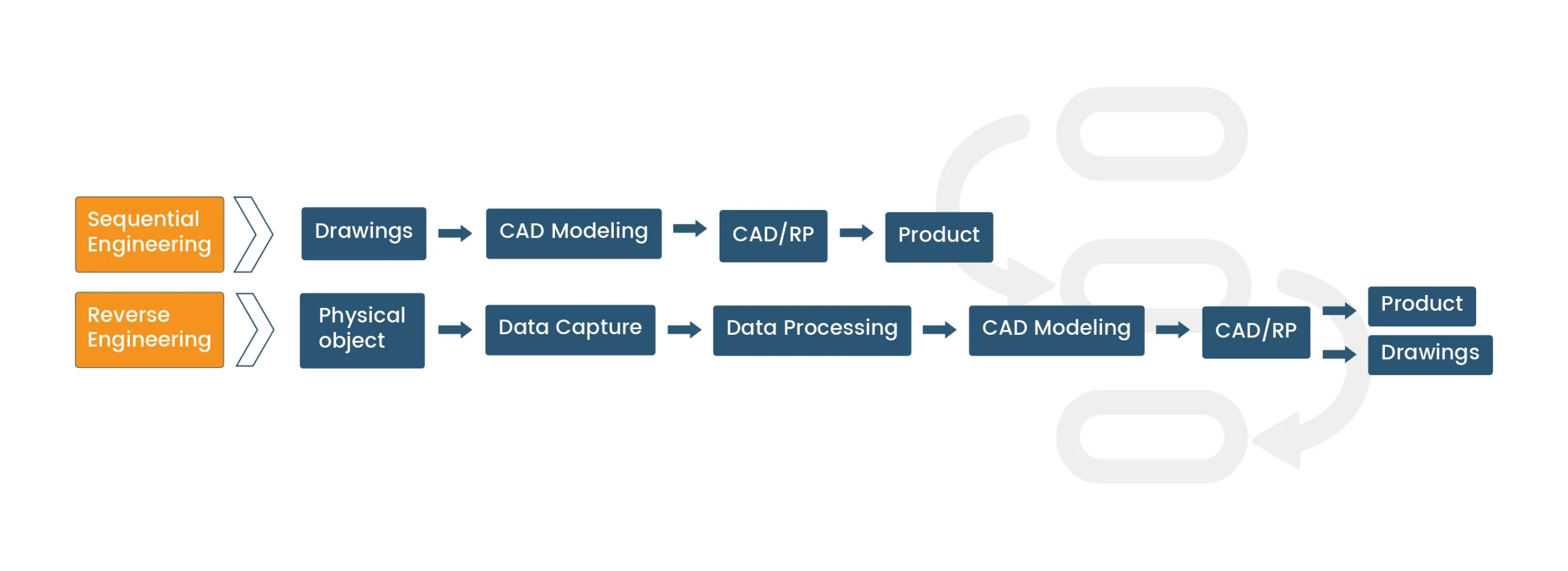

Data capture and modeling, which is also called reverse engineering, is a process of product design technology reproduction.

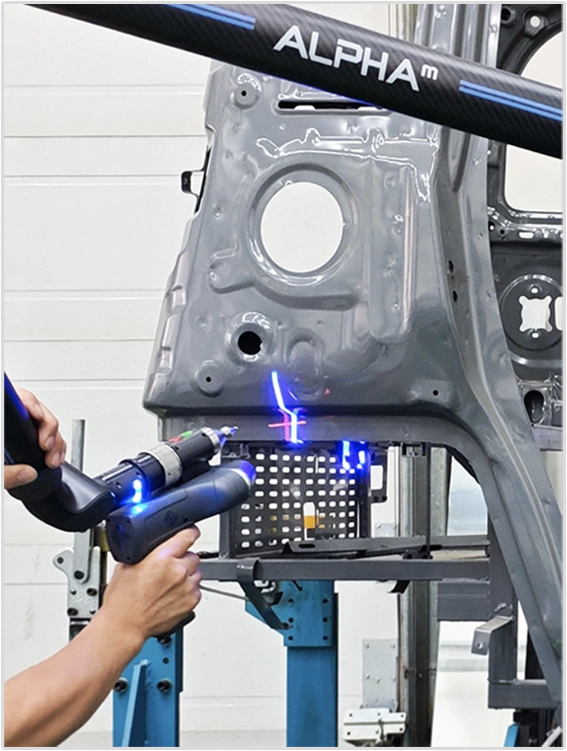

It means the target product is scanned and restored by PMT Laser Scan Arm (portable coordinate measuring machine), and reverse analysis and research are carried out, so as to deduce and derive the size and specifications of the product and other elements, and judge whether the product is qualified or not.

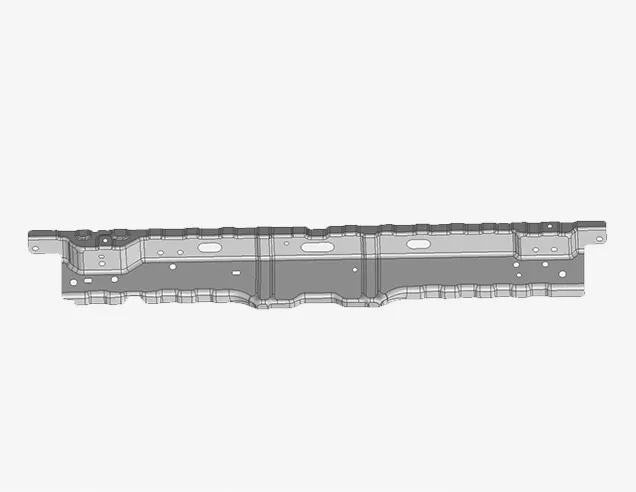

There are two main forms of data modeling: one is to trim and combine the specific solid line features or the detected point data in the design software to achieve modeling. This is usually suitable for hard workpieces with regular and simple structures. The second, which is more commonly used, is to use a scanned 3D model for modeling.

Due to the dense point cloud of scanning data, the physical object can be displayed more comprehensively and vividly. The designer constructs the line by intercepting the contour line and then constructs the 3D drawing of the physical object through line stretching, rotation, sweeping, lofting, Boolean operation, etc.. The dimensional information can be attached during the process, and then the CAD drawing is converted into production and processing drawings.

Precision Measurement of Mounting Holes

PMT Laser ScanArm offers both contact and non-contact measurement solutions and does not require any additional pasting or tools. Therefore, it can not only provide reverse data in the prototype phase, but also can be designed and verified in the sampling stage. And even in the mass production, the machine can conduct rapid sampling with its detection function and thus help guarantee the consistency of process production based on the given sampling results.

“The sectional measurement of the 10,000-ton hull requires scaffolding, which is dangerous and inefficient. We have been struggling with how to inspect such huge objects. The PMT’s laser scanning arm enables partial-to-global model stitching with 99.5% data integrity. Scaffold-free measurements tripled design efficiency, shortening project timelines by two months.”

“I have been struggling with choosing brands in the beginning. The PMT’s coordinated measuring machine stood out for its robust structure and precision. PMT company has years of research and development in the measurement field. Its CMM machine now resolves previously undetectable parameters, delivering professional reports that boost competitiveness.”

“There are many similar factories near our company and by chance I found some companies using articulated arms to measure their parts. After thorough comparisons, the PMT’s articulated arm CMM won us over with its technological design, flexibility, and high accuracy. It’s now integral to our inspection processes.”