In the application of coordinate measuring machine measurement, the spiral pump, also known as the Archimedes’ screw or water screw in the engineering machinery industry, is a screw that uses the rotation of blades to progressively moving fluid along the screw’s axle. Due to its unique structure and performance advantages, the screw pump has been widely used in various scenarios in the mechanical manufacturing field.

In the application of coordinate measuring machine measurement, the spiral pump, also known as the Archimedes’ screw or water screw in the engineering machinery industry, is a screw that uses the rotation of blades to progressively moving fluid along the screw’s axle. Due to its unique structure and performance advantages, the screw pump has been widely used in various scenarios in the mechanical manufacturing field.

Challenges in Screw Pump Precision Manufacturing

The performance of a screw pump is significantly influenced by the manufacturing precision of its key components, particularly the dimensions and gap of the screw. Below are the primary challenges encountered in the manufacturing process of screw pumps:

1.Dimension Requirements

①The outer diameter, pitch, lead, and other dimensions of the screw must be controlled within micrometer-level tolerance (usually ±0.01 to ±0.05mm).

②For double-screw or triple-screw pumps, the meshing gap between screws must be uniform (typically between 0.05 and 0.15mm). A large gap can lead to internal leakage, while a small gap may result in jamming or wear.

2.Consequences of Poor Precision

①Fluid Leakage: A large gap or deviation can cause the fluid to flow back from the high-pressure area to the low-pressure area, then reducing volumetric efficiency.

②Efficiency Decrease: Increased internal leakage and friction lead to higher energy consumption.

③Vibration and Noise: Uneven meshing or axis deviation can cause mechanical vibrations and noise.

④Wear Intensify: Surface roughness or insufficient hardness can shorten the screw’s lifespan, especially when transporting fluid containing particles.

⑤Jamming Risk: A small gap or uncompensated thermal expansion can lead to screw lock due to temperature changes.

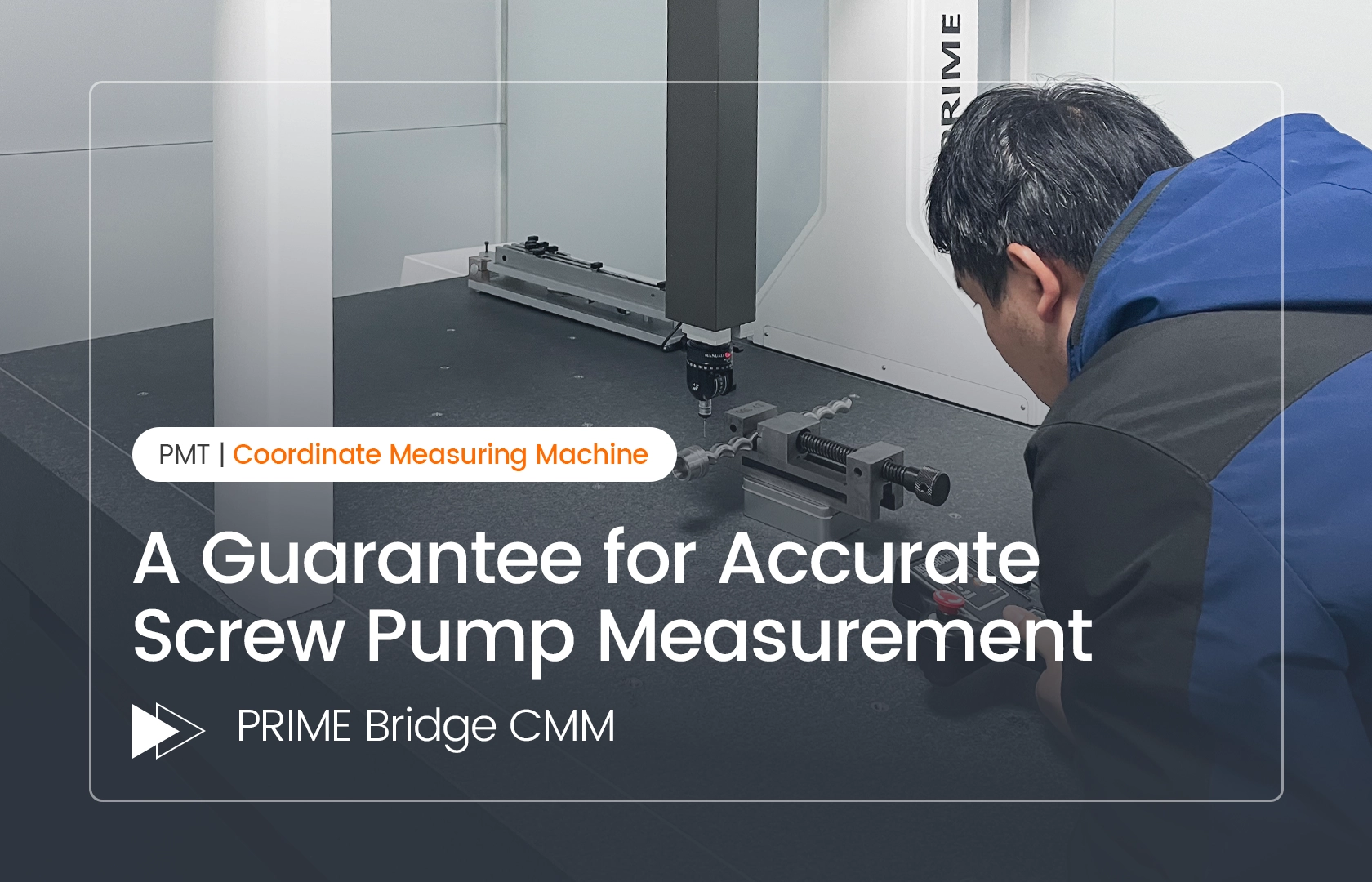

PMT CMM Precision Measurement Solution

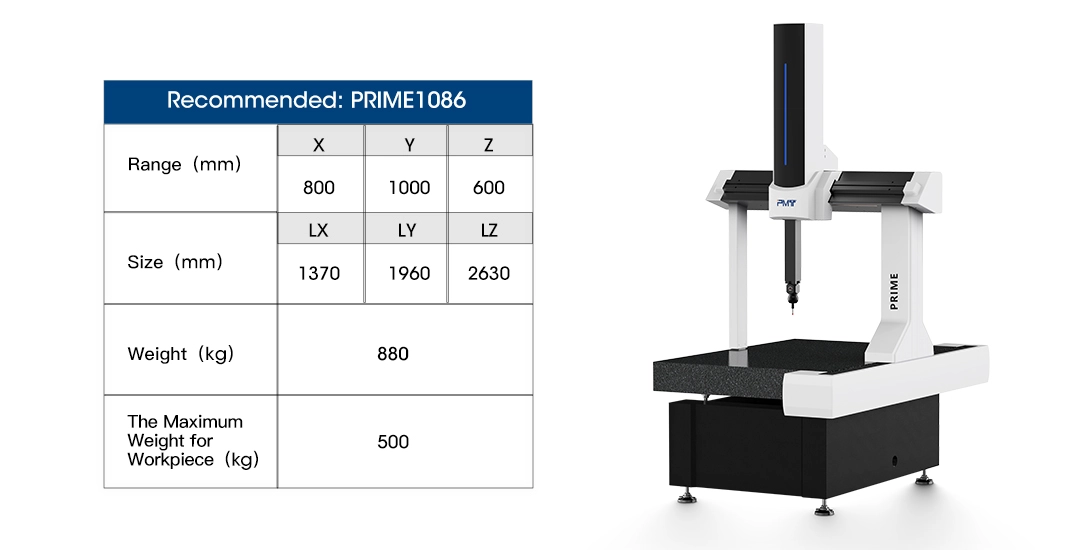

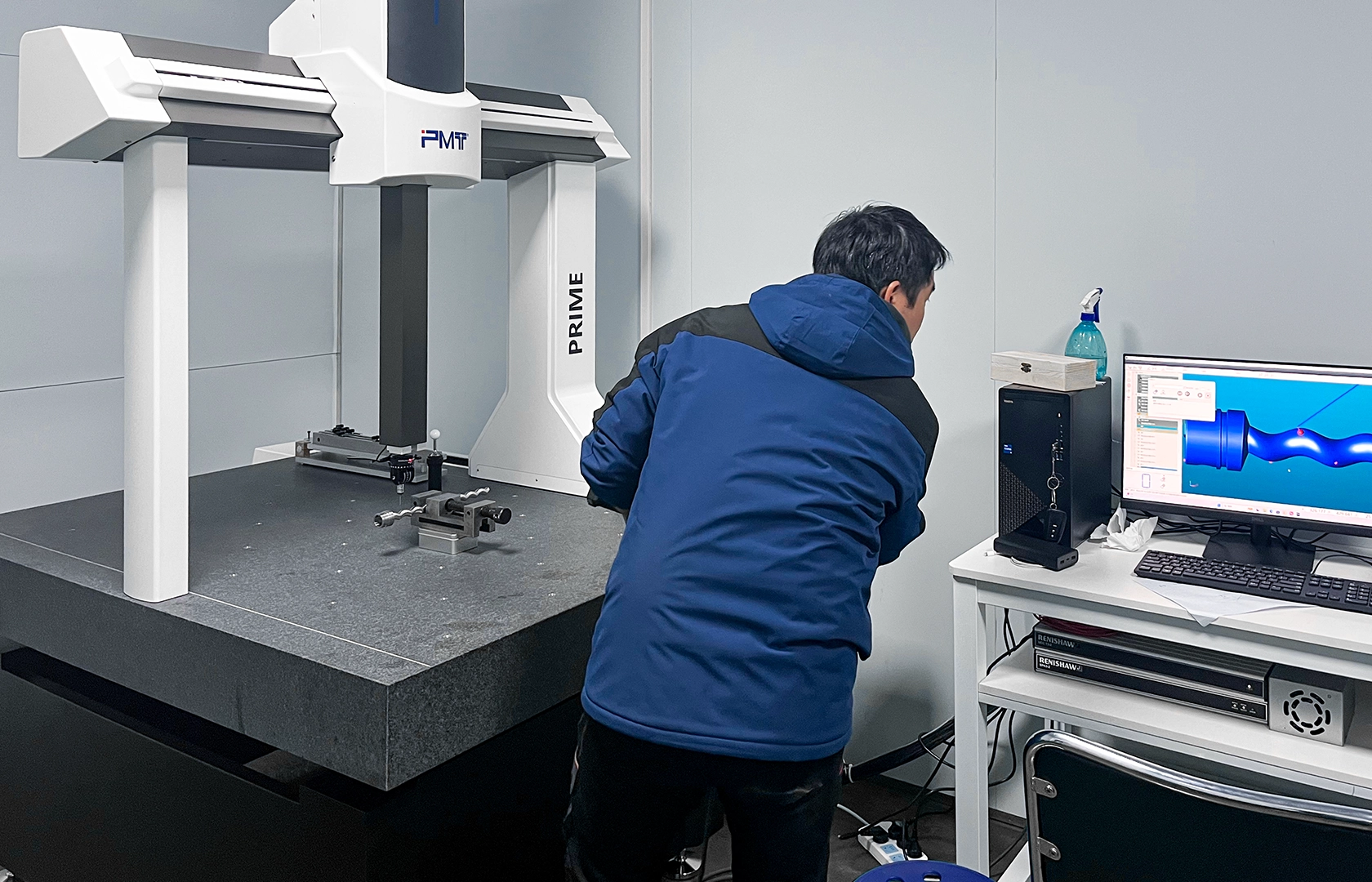

Recommended Configuration

Measurement Range: 800*100*600mm, which can meet the measurement needs for most of screw pump parts.

Probe Head: MH20i, a manual articulating probe head kit, easy to operate and highly adaptable.

Stylus: D4*L20, which is suitable for measuring a variety of materials and shapes.

Measurement Angles: A0B0, A90B90, A90B-90, ensuring the accuracy of measurement results.

Measurement Process

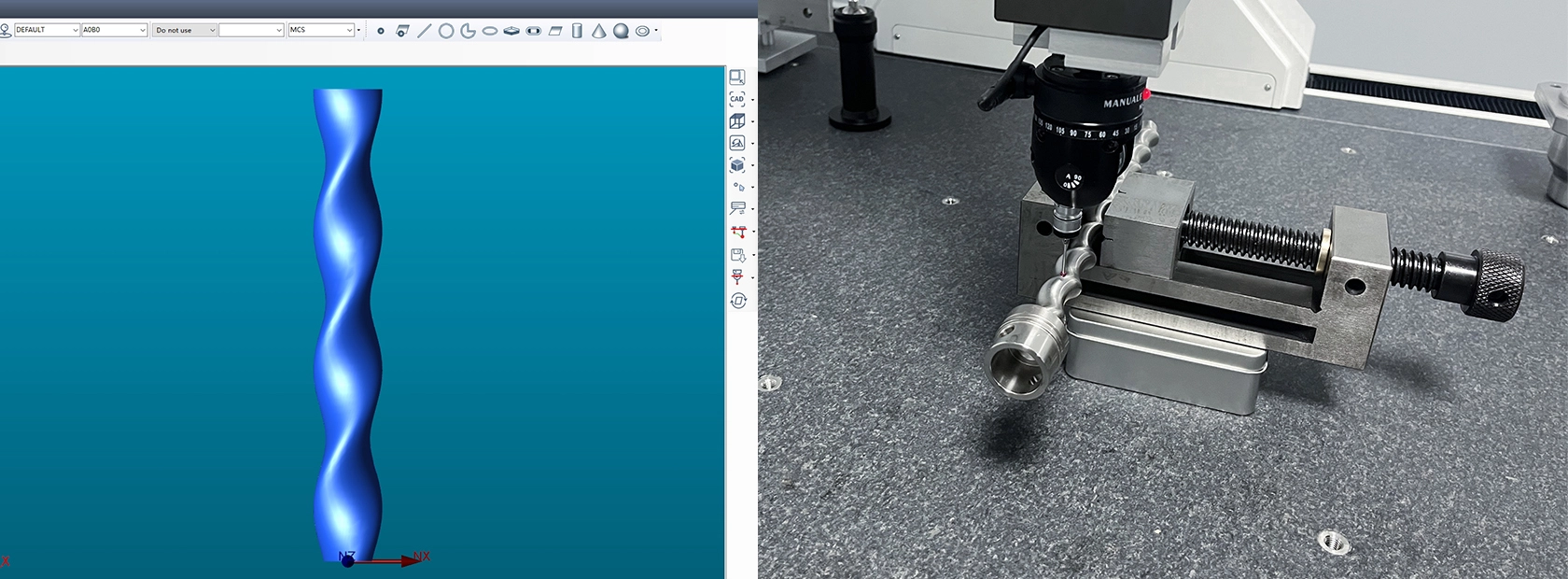

1.Import the CAD Model: Import the CAD model into the measurement software to establish a datum for subsequent measurements.

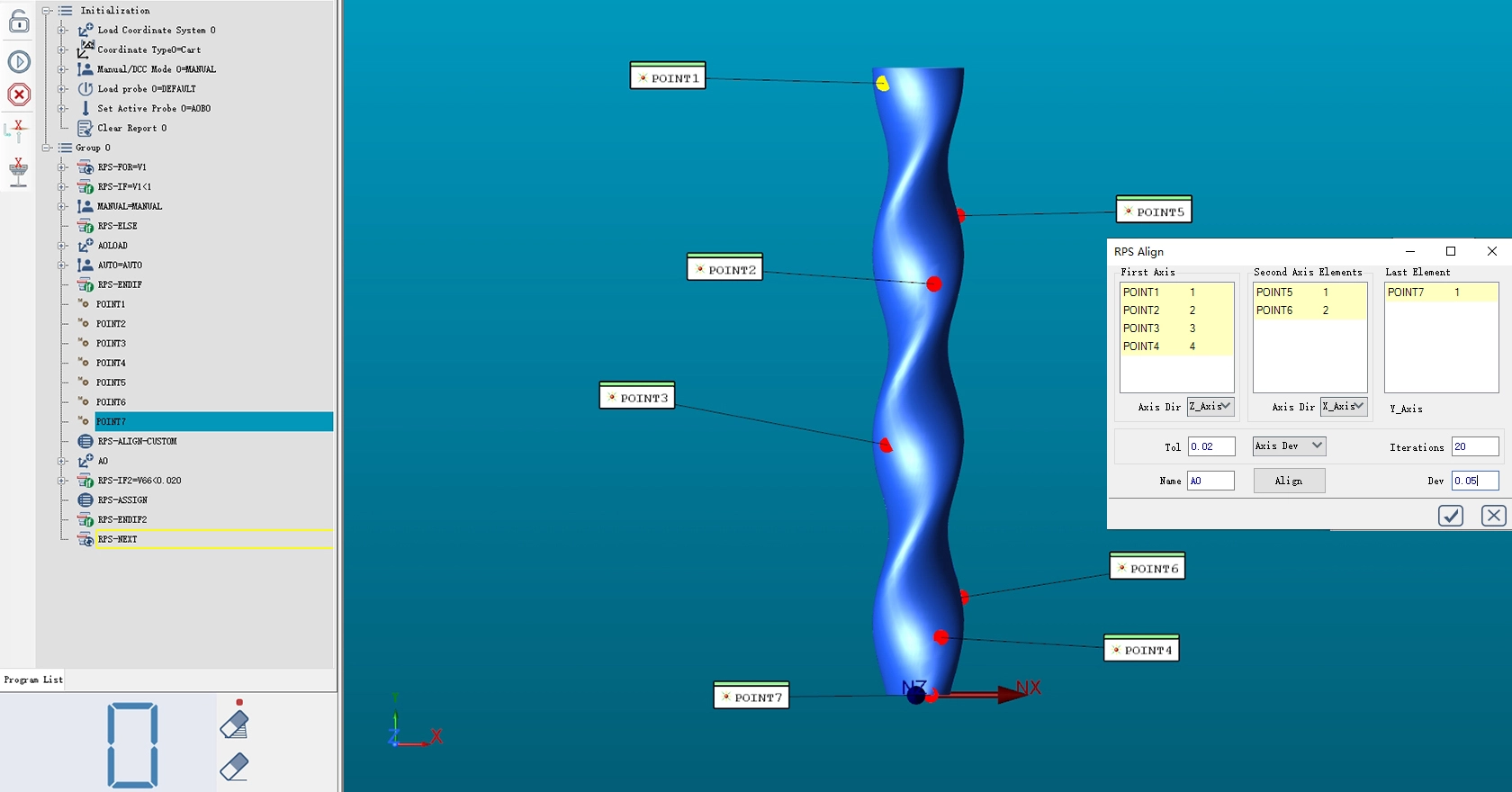

2.Establish the Coordinate System: Use the iterative method to select the point-controlled axis and set the maximum number of iterations and iteration deviation to ensure the accuracy of the coordinate system.

3.Manual Measurement: Manually measure key points, with the software automatically iterating and optimizing to obtain the best values.

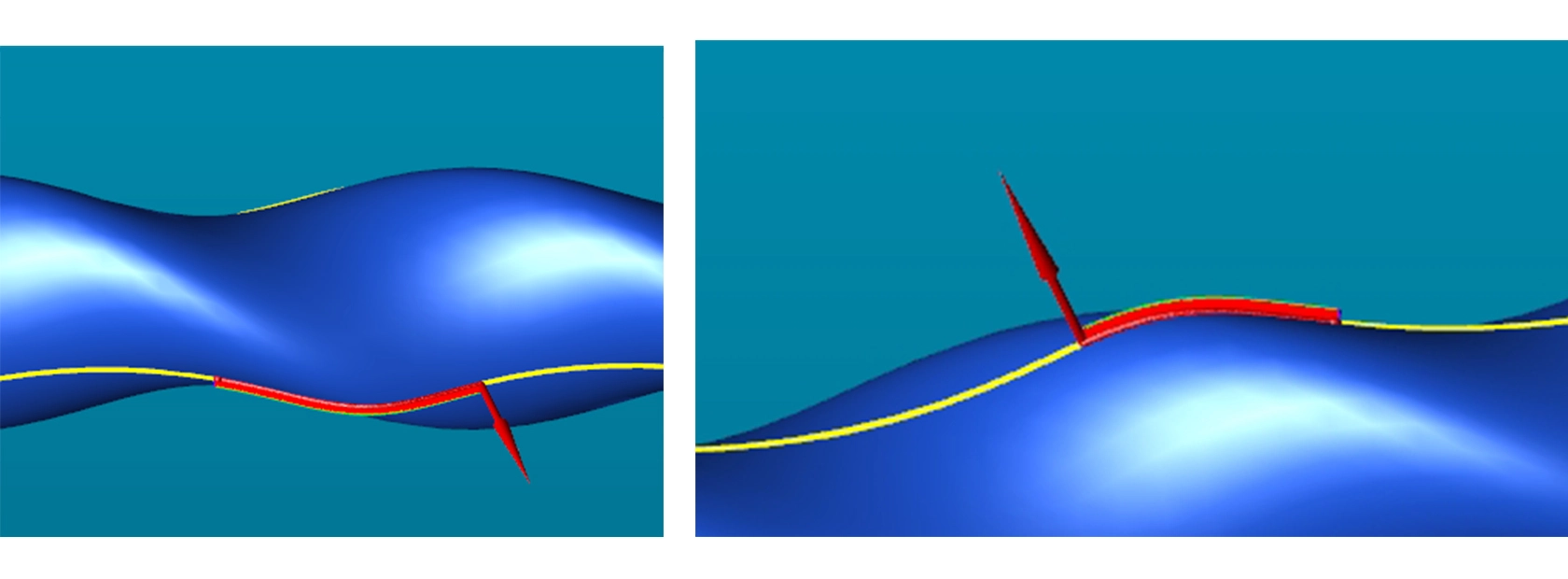

4.Section Scanning: Use the section scanning function to measure the screw’s surface profile to ensure its accuracy.

5.Construction and Evaluation: Use the construction function to extract the apex of surface and evaluate the outer/inner diameter distances to ensure the dimensions meet design requirements.

Core Advantages of PMT PRIME Coordinate Measuring Machine

The PMT PRIME Coordinate Measuring Machine stands out as the ideal choice for screw pump manufacturing industries owing to the following core advantages:

1.High-Precision Measurement: PMT CMMs meet the micrometer-level tolerance requirements of screw pumps, ensuring product quality.

2.High-Efficiency Measurement: PMT CMMs’ automated measurement processes significantly enhance inspection efficiency.

3.Professional Support: PMT CMMs provide a one-stop service from equipment selection to measurement solution design.

4.Wide Applicability: PMT CMMs are suitable for measuring a variety of precision parts, including screw pumps, semiconductor equipment, etc.

Conclusion

As a critical equipment in the fluid transport field, the performance of a screw pump is closely bound up with its manufacturing precision. The PMT PRIME CMM provides reliable measurement solutions that are widely applicable within the screw pump industry. What’s more, the PMT coordinate measuring machines have empowered enterprises to continuously improve product quality and enhance production efficiency.